| ||

UNITED STATES | ||

SECURITIES AND EXCHANGE COMMISSION | ||

Washington, D.C. 20549 | ||

| ||

FORM 10-K | ||

| ||

(Mark One) | ||

[X] ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 | ||

For the fiscal year ended December 31, 2013 | ||

OR | ||

[ ] TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 | ||

For the transition period from |

| to |

Commission File Number: 001-11307-01 | ||

Freeport-McMoRan Copper & Gold Inc. | ||

(Exact name of registrant as specified in its charter) | ||

Delaware | 74-2480931 |

(State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification No.) |

|

|

333 North Central Avenue |

|

Phoenix, Arizona | 85004-2189 |

(Address of principal executive offices) | (Zip Code) |

| |

(602) 366-8100 | |

(Registrant's telephone number, including area code) | |

Securities registered pursuant to Section 12(b) of the Act:

Title of each class |

| Name of each exchange on which registered |

Common Stock, par value $0.10 per share |

| New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act ☑ Yes ¨ No

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. ¨ Yes ☑ No

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. ☑ Yes ¨ No

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). ☑ Yes ¨ No

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of the registrant's knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ☑

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See the definitions of "large accelerated filer," "accelerated filer" and "smaller reporting company" in Rule 12b-2 of the Exchange Act. ☑ Large accelerated filer ¨ Accelerated filer ¨ Non-accelerated filer ¨ Smaller reporting company

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). ¨ Yes ☑ No

The aggregate market value of common stock held by non-affiliates of the registrant was $34.5 billion on February 14, 2014 , and $28.3 billion on June 28, 2013.

Common stock issued and outstanding was 1,038,417,983 shares on February 14, 2014 , and 1,037,809,895 shares on June 28, 2013 .

Portions of our proxy statement for our 2014 annual meeting of stockholders are incorporated by reference into Part III (Items 10, 11, 12, 13 and 14) of this report. |

FREEPORT-McMoRan COPPER & GOLD INC.

TABLE OF CONTENTS | |

|

|

| Page |

Part I | 1 |

Items 1. and 2. Business and Properties | 1 |

Item 1A. Risk Factors | 48 |

Item 1B. Unresolved Staff Comments | 66 |

Item 3. Legal Proceedings | 66 |

Item 4. Mine Safety Disclosures | 68 |

Executive Officers of the Registrant | 68 |

|

|

Part II | 69 |

Item 5. Market for Registrant's Common Equity, Related Stockholder Matters |

|

and Issuer Purchases of Equity Securities | 69 |

Item 6. Selected Financial Data | 71 |

Items 7. and 7A. Management's Discussion and Analysis of Financial Condition and Results |

|

of Operations and Quantitative and Qualitative Disclosures about Market Risk | 75 |

Item 8. Financial Statements and Supplementary Data | 134 |

Item 9. Changes in and Disagreements with Accountants on Accounting and Financial Disclosure | 208 |

Item 9A. Controls and Procedures | 208 |

Item 9B. Other Information | 209 |

|

|

Part III | 209 |

Item 10. Directors, Executive Officers and Corporate Governance | 209 |

Item 11. Executive Compensation | 209 |

Item 12. Security Ownership of Certain Beneficial Owners and Management and |

|

Related Stockholder Matters | 209 |

Item 13. Certain Relationships and Related Transactions, and Director Independence | 210 |

Item 14. Principal Accounting Fees and Services | 210 |

|

|

Part IV | 210 |

Item 15. Exhibits, Financial Statement Schedules | 210 |

|

|

Signatures | S-1 |

|

|

Index to Financial Statements | F-1 |

|

|

Exhibit Index | E-1 |

i

Table of Contents

PART I

Items 1. and 2. Business and Properties.

All of our periodic reports filed with the United States (U.S.) Securities and Exchange Commission (SEC) pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 1934, as amended, are available, free of charge, through our website, www.fcx.com, including our annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K and any amendments to those reports. These reports and amendments are available through our website as soon as reasonably practicable after we electronically file or furnish such material to the SEC.

References to "we," "us" and "our" refer to Freeport-McMoRan Copper & Gold Inc. (FCX) and its consolidated subsidiaries. References to "Notes" refer to the Notes to Consolidated Financial Statements included herein (refer to Item 8), and references to "MD&A" refer to Management's Discussion and Analysis of Financial Condition and Results of Operations included herein (refer to Item 7).

GENERAL

As further discussed in Note 2 , during second-quarter 2013, we completed the acquisitions of Plains Exploration & Production Company (PXP) and McMoRan Exploration Co. (MMR). With these acquisitions, we are a premier U.S.-based natural resource company with an industry leading global portfolio of mineral assets, significant oil and natural gas resources and a growing production profile. Our principal executive offices are in Phoenix, Arizona, and our company was incorporated under the laws of the state of Delaware on November 10, 1987.

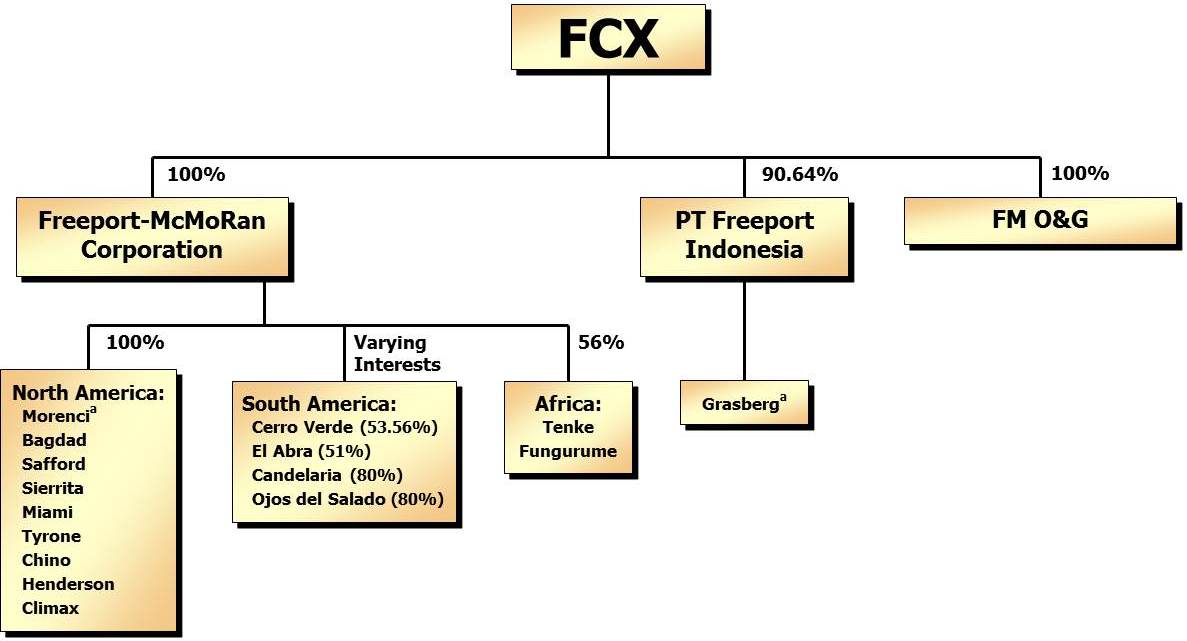

Our portfolio of assets includes the Grasberg minerals district in Indonesia, one of the world's largest copper and gold deposits, significant mining operations in North and South America, the Tenke Fungurume (Tenke) minerals district in the Democratic Republic of Congo (DRC) in Africa and significant oil and natural gas assets in North America. Below is FCX's ownership interest in its operating mines and its oil and gas business through its subsidiary, FCX Oil & Gas Inc. (FM O&G), at December 31, 2013 :

a. | We have an 85 percent interest in Morenci and our direct ownership in PT Freeport Indonesia (PT-FI) totals 81.28 percent. Refer to Note 3 for further discussion of our ownership in subsidiaries and joint ventures. |

1

Table of Contents

Mining

At December 31, 2013 , consolidated recoverable proven and probable mineral reserves totaled 111.2 billion pounds of copper, 31.3 million ounces of gold, 3.26 billion pounds of molybdenum, 308.5 million ounces of silver and 0.87 billion pounds of cobalt. Following is a summary of our consolidated recoverable proven and probable mineral reserves at December 31, 2013 , by geographic location (refer to "Mining Operations" for further discussion):

| Copper |

| Gold |

| Molybdenum |

| Silver |

| Cobalt |

North America | 33% |

| 1% |

| 78% |

| 28% |

| - |

South America | 33% |

| 4% |

| 22% |

| 35% |

| - |

Indonesia | 27% |

| 95% |

| - |

| 37% |

| - |

Africa | 7% |

| - |

| - |

| - |

| 100% |

| 100% |

| 100% |

| 100% |

| 100% |

| 100% |

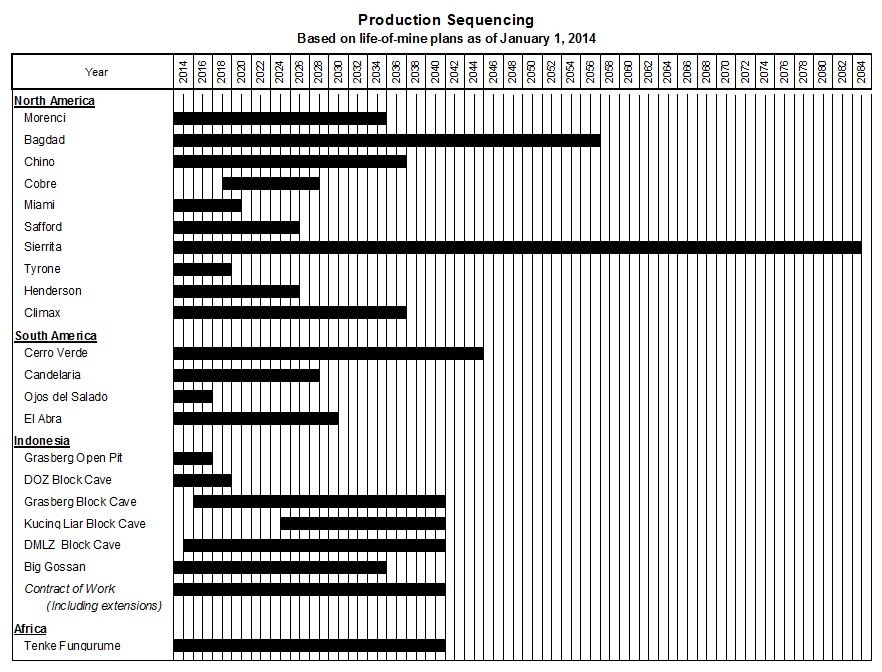

In North America, we have seven operating copper mines – Morenci, Bagdad, Safford, Sierrita and Miami in Arizona, and Chino and Tyrone in New Mexico, and two operating molybdenum mines – Henderson and Climax in Colorado. In addition to copper, certain of our North America copper mines also produce molybdenum concentrates.

In South America, we have four operating copper mines – Cerro Verde in Peru, and El Abra, Candelaria and Ojos del Salado in Chile. In addition to copper, the Cerro Verde mine also produces molybdenum concentrates, and the Candelaria and Ojos del Salado mines produce gold and silver.

In Indonesia, our subsidiary PT-FI operates the mines in the Grasberg minerals district. In addition to copper, the Grasberg minerals district also produces significant quantities of gold and silver.

In Africa, our subsidiary Tenke Fungurume Mining S.A.R.L. (TFM) operates the mines in the Tenke minerals district. In addition to copper, the Tenke minerals district also produces cobalt hydroxide.

Following is a summary of our consolidated copper, gold and molybdenum production for the year 2013 by geographic location (refer to "Mining Operations" for further information):

| Copper |

| Gold |

| Molybdenum |

|

North America | 35% |

| 1% |

| 86% |

|

South America | 32% |

| 8% |

| 14% |

|

Indonesia | 22% |

| 91% |

| - |

|

Africa | 11% |

| - |

| - |

|

| 100% |

| 100% |

| 100% |

|

2

Table of Contents

Oil and Gas

At December 31, 2013, our estimated proved oil and natural gas reserves totaled 464 million barrels of oil equivalents (MMBOE). All of our proved oil and natural gas reserves were located in the U.S., with 80 percent comprised of oil (including natural gas liquids, or NGLs) and 66 percent represented by proved developed reserves. Refer to "Oil and Gas Operations" for further discussion.

Our oil and gas operations include oil production facilities and growth potential in the Deepwater Gulf of Mexico (GOM), oil production from the onshore Eagle Ford shale play in Texas, oil production facilities onshore and offshore California, onshore natural gas resources in the Haynesville shale play in Louisiana, natural gas production from the Madden area in central Wyoming, and an industry-leading position in the emerging shallow-water Inboard Lower Tertiary/Cretaceous natural gas trend on the Shelf of the GOM and onshore in South Louisiana.

The locations of our U.S. oil and gas operations are shown on the map below:

COPPER, GOLD, MOLYBDENUM AND OIL

Following provides a brief discussion of our primary natural resources, copper, gold, molybdenum and oil. For further discussion of historical market prices of these metals refer to MD&A.

Copper

Copper is an internationally traded commodity, and its prices are determined by the major metals exchanges – the London Metal Exchange (LME), New York Mercantile Exchange (NYMEX) and Shanghai Futures Exchange (SHFE). Prices on these exchanges generally reflect the worldwide balance of copper supply and demand, and can be volatile and cyclical. During 2013 , LME spot copper prices ranged from a low of $3.01 per pound to a high of $3.74 per pound and averaged $3.31 per pound. In general, demand for copper reflects the rate of underlying world economic growth, particularly in industrial production and construction. According to Wood Mackenzie, a widely followed independent metals market consultant, copper's end-use markets (and their estimated shares of total consumption) are:

Electrical applications | 34 | % |

Construction | 31 | % |

Industrial machinery | 13 | % |

Transportation | 13 | % |

Consumer products | 9 | % |

| 100 | % |

3

Table of Contents

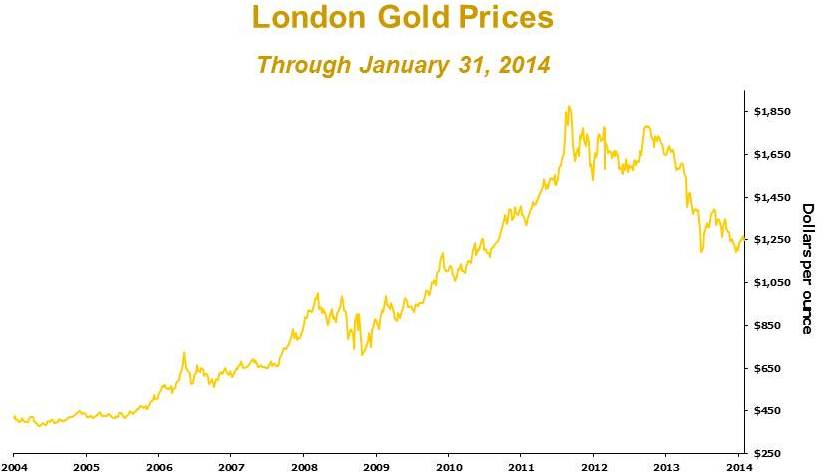

Gold

Gold is used for jewelry, coinage and bullion as well as various industrial and electronic applications. Gold can be readily sold on numerous markets throughout the world. Benchmark prices are generally based on London Bullion Market Association (London) PM quotations. During 2013 , London PM gold prices ranged from a low of $1,192 per ounce to a high of $1,694 per ounce and averaged $1,405 per ounce.

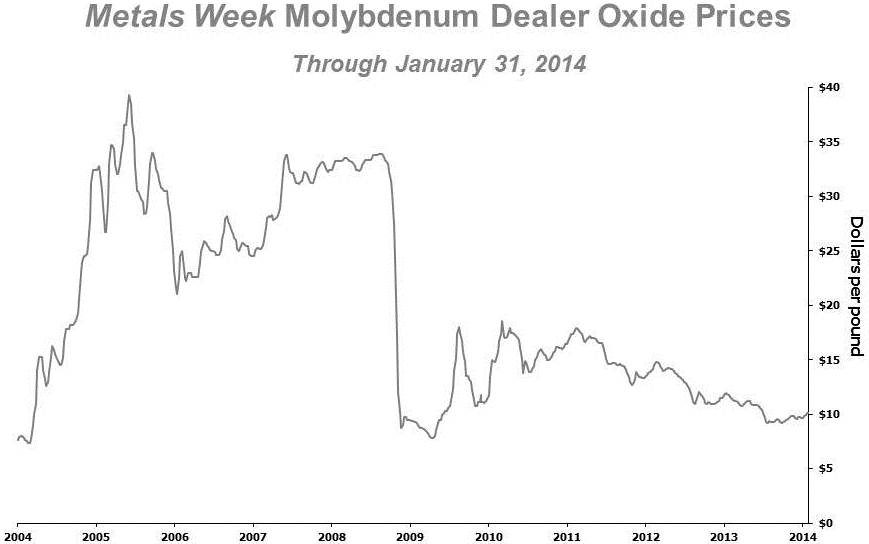

Molybdenum

Molybdenum is a key alloying element in steel and the raw material for several chemical-grade products used in catalysts, lubrication, smoke suppression, corrosion inhibition and pigmentation. Molybdenum, as a high-purity metal, is also used in electronics such as flat-panel displays and in super alloys used in aerospace. Reference prices for molybdenum are available in several publications, including Metals Week , Ryan's Notes and Metal Bulletin . During 2013 , the weekly average price of molybdenum quoted by Metals Week ranged from a low of $9.18 per pound to a high of $11.95 per pound and averaged $10.32 per pound.

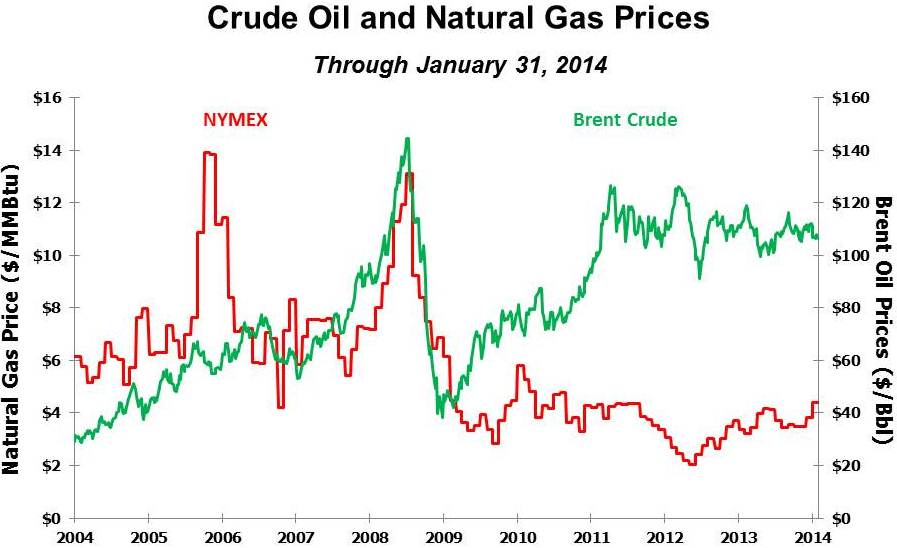

Oil

Oil products include transportation fuels, fuel oils for heating and electricity generation, asphalt and road oil, and the feedstocks used to make chemicals, plastics and synthetic materials. The price of crude oil is set in the global marketplace, with prices largely determined by regional benchmarks, including Brent, West Texas Intermediate (WTI) and Light Louisiana Sweet (LLS). Prices generally reflect the worldwide supply and demand balance, and can be volatile. During 2013, the Brent crude oil price ranged from a low of $97.69 per barrel to a high of $118.90 per barrel and averaged $108.68 per barrel.

PRODUCTS AND SALES

FCX's consolidated revenues for 2013 primarily included sales of copper ( 69 percent ), oil ( 11 percent ), gold ( 8 percent ) and molybdenum ( 5 percent ). Oil sales reflect sales for the seven-month period following the acquisition of our oil and gas operations. Refer to Note 16 for a summary of our consolidated revenues and operating income by business segment and geographic area.

PT-FI's sales to PT Smelting (PT-FI's 25 percent owned copper smelter and refinery in Indonesia - refer to "Mining Operations - Smelting Facilities and Other Mining Properties" for further discussion) represented 8 percent of our consolidated revenues in 2013 , and 11 percent in 2012 and 2011 . No other customer accounted for more than 10 percent of our consolidated revenues in any of the past three years.

Copper Products

We are one of the world's leading producers of copper concentrate, cathode and continuous cast copper rod. During 2013 , 49 percent of our mined copper was sold in concentrate, 28 percent as cathode and 23 percent as rod.

Our copper ore is generally processed either by smelting and refining or by solution extraction and electrowinning (SX/EW). Before being subject to the smelting and refining process, ore is crushed and treated to produce a copper concentrate with copper content of approximately 20 to 30 percent. Copper concentrate is then smelted ( i.e. , subjected to extreme heat) to produce copper anodes, which weigh between 800 and 900 pounds each and have an average copper content of 99.5 percent. The anodes are further treated by electrolytic refining to produce copper cathodes, which weigh between 100 and 350 pounds each and have an average copper content of 99.99 percent. For ore subject to the SX/EW process, copper is extracted from the ore by dissolving it with a weak sulphuric acid solution. The copper content of the solution is increased in two additional solution-extraction stages and then the copper-bearing solution undergoes an electrowinning process to produce cathode that is, on average, 99.99 percent copper. Our copper cathodes are used as the raw material input for copper rod, brass mill products and for other uses.

Copper Concentrate . We produce copper concentrate at eight of our mines, of which PT-FI is our largest producer. In North America, copper concentrate is produced at our Morenci, Bagdad, Sierrita and Chino mines, and is generally shipped to our Miami smelter in Arizona. In South America, we produce copper concentrate at our Cerro Verde, Candelaria and Ojos del Salado mines.

4

Table of Contents

Copper Cathode . We produce copper cathode at our electrolytic refinery located in El Paso, Texas, and at 10 of our mines. In North America, SX/EW cathode is produced from our Morenci, Bagdad, Safford, Sierrita, Miami, Chino and Tyrone mines; in South America from our Cerro Verde and El Abra mines; and from the Tenke minerals district in Africa . Atlantic Copper S.L.U. (Atlantic Copper, our wholly owned copper smelting and refining unit in Spain - refer to "Mining Operations - Smelting Facilities and Other Mining Properties" for further discussion) and PT Smelting also produce copper cathode.

Continuous Cast Copper Rod . We manufacture continuous cast copper rod at our facilities in El Paso, Texas; Norwich, Connecticut; and Miami, Arizona, primarily using copper cathode produced at our North America copper mines.

Copper Sales

North America . The majority of the copper produced at our North America copper mines and refined in our El Paso, Texas, refinery is consumed at our rod plants. The remainder of our North America copper production is sold in the form of copper cathode or copper concentrate under U.S. dollar-denominated annual contracts. Cathode and rod contract prices are generally based on the prevailing Commodity Exchange Inc. (COMEX - a division of NYMEX) monthly average spot price for the month of shipment and include a premium. Generally, copper rod is sold to wire and cable manufacturers, while cathode is sold to rod, brass or tube fabricators. During 2013 , four percent of our North America mines' copper sales volumes were shipped to Atlantic Copper in the form of copper concentrate.

South America . Production from our South America mines is sold as copper concentrate or copper cathode under U.S. dollar-denominated, annual and multi-year contracts. Our South America mines generally sell approximately 60 to 70 percent of copper production in concentrate and the rest as cathode. During 2013 , 12 percent of our South America mines' copper sales volumes were shipped to Atlantic Copper in the form of copper concentrate.

Substantially all of South America's copper concentrate and cathode sales contracts provide final copper pricing in a specified future month (generally one to four months from the shipment date) primarily based on quoted LME monthly average spot copper prices. Revenues from South America's concentrate sales are recorded net of treatment and refining charges ( i.e., fees paid to smelters and refiners that are generally negotiated annually), including any applicable price participation charges that are based on the market price of copper. In addition, because a portion of the metals contained in copper concentrates is unrecoverable from the smelting process, revenues from South America's concentrate sales are also recorded net of allowances for unrecoverable metals, which are a negotiated term of the contracts and vary by customer.

Indonesia . PT-FI sells its production in the form of copper concentrate, which contains significant quantities of gold and silver, under U.S. dollar-denominated, long-term contracts. PT-FI also sells a small amount of copper concentrates in the spot market. Following is a summary of PT-FI's aggregate percentage concentrate sales to PT Smelting, Atlantic Copper and third parties for the last three years:

| 2013 |

| 2012 |

| 2011 | |||

PT Smelting | 41 | % |

| 52 | % |

| 44 | % |

Atlantic Copper | 9 | % |

| 11 | % |

| 10 | % |

Third parties | 50 | % |

| 37 | % |

| 46 | % |

| 100 | % |

| 100 | % |

| 100 | % |

Substantially all of PT-FI's concentrate sales contracts provide final copper pricing in a specified future month (generally one to four months from the shipment date) primarily based on quoted LME monthly average spot copper prices. Revenues from PT-FI's concentrate sales are recorded net of royalties, treatment and refining charges, and allowances for unrecoverable metals.

Africa . TFM sells its production in the form of copper cathode under U.S. dollar-denominated contracts. Substantially all of TFM's cathode sales provide final copper pricing in the month after the shipment date based on quoted LME monthly average spot copper prices. Revenues from TFM's cathode sales are recorded net of royalties and also include adjustments for point-of-sale transportation costs that are negotiated in customer contracts.

Gold Products and Sales

We produce gold, mostly from the Grasberg minerals district. Gold is primarily sold as a component of our copper concentrate or in slimes, which are a product of the smelting and refining process. Gold generally is priced at the average London price for a specified month near the month of shipment. Revenues from gold sold as a component

5

Table of Contents

of our copper concentrate are recorded net of treatment and refining charges. Revenues from gold sold in slimes are recorded net of refining charges.

Molybdenum Products and Sales

We are the world's largest producer of molybdenum and molybdenum-based chemicals. In addition to production from our Henderson and Climax molybdenum mines, we produce molybdenum concentrate at certain of our North America copper mines, and at our Cerro Verde copper mine in Peru. The majority of our molybdenum concentrates are processed in our own conversion facilities. Molybdenum generally is priced based on the average Metals Week price for the month prior to the month of shipment.

Cobalt and Silver Products and Sales

We produce cobalt hydroxide at the Tenke minerals district. Cobalt hydroxide is priced at a discount to the average monthly low price published by Metal Bulletin for a specified month near the month of shipment. Beginning in 2014, we will begin using LME-based pricing for our cobalt hydroxide sales contracts.

We also produce silver as a component of our copper concentrate or in slimes. Silver generally is priced at the average London price for a specified month near the month of shipment.

Oil and Gas Products and Sales

We produce and sell oil and gas throughout the U.S. Our oil production is primarily sold under contracts with prices based upon regional benchmarks. Approximately 50 percent of our gas production is sold monthly based on published index pricing, with the remainder priced daily on the spot market.

Approximately 68 percent of our California production is attributable to heavy crude oil, which is primarily sold under a long-term contract with prices based upon regional benchmarks. We sell a large portion of our Eagle Ford production to third parties using a LLS-based pricing mechanism. In the GOM, our share of oil and gas production is sold under a series of contracts pursuant to which crude oil is sold directly to refineries in the Gulf Coast regions of Texas and Louisiana at prices based on widely-used industry benchmarks.

LABOR MATTERS

At December 31, 2013 , we employed approximately 36,100 people (13,300 in the U.S., 12,300 in Indonesia, 5,800 in South America, 3,300 in Africa and 1,400 in Europe and other locations). Additionally, we have contractors that have personnel at many of our operations, including approximately 19,400 at our Grasberg minerals district, 12,800 at our South America mining operations, 3,800 at our Tenke minerals district, 1,900 in the U.S. and 500 in Europe and other locations. The number of employees represented by unions at December 31, 2013, and the expiration date of the applicable union agreements are listed below. Refer to Item 1A. "Risk Factors" for further information on labor matters.

Location | Number of Unions | Number of Union- Represented Employees | Expiration Date | |||

PT-FI – Indonesia | 1 | 9,356 | | September 2015 |

| |

TFM – DRC | 6 | 3,327 | | N/A | a | |

Cerro Verde – Peru | 2 | 1,846 | | August 2018 | b | |

El Abra – Chile | 2 | 1,007 | | May 2016 |

| |

Candelaria – Chile | 2 | 904 | | December 2016 |

| |

Atlantic Copper – Spain | 2 | 450 | | December 2015 |

| |

Kokkola - Finland | 3 | 410 | | November 2016 |

| |

Chino – New Mexico | 1 | 352 | | November 2014 |

| |

Rotterdam – The Netherlands | 2 | 62 | | March 2015 |

| |

Aurex – Chile | 1 | 38 | | December 2017 |

| |

Bayway – New Jersey | 1 | 37 | | April 2016 |

| |

Stowmarket – United Kingdom | 1 | 31 | | May 2014 |

| |

6

Table of Contents

a. | The Collective Labor Agreement (CLA) between TFM and its workers' unions has no expiration date, but can be amended at any time in accordance with an established process. Additionally, in September 2012 TFM negotiated a 4-year salary scale with union-represented employees. |

b. | In November 2013, Cerro Verde signed a new four-year CLA, which is effective September 1, 2014, upon the expiration of the current agreement. |

ENVIRONMENTAL AND RECLAMATION MATTERS

The cost of complying with environmental laws is a fundamental and substantial cost of our business. For information about environmental regulation, litigation and related costs, refer to Item 1A. "Risk Factors" and Notes 1 and 12 .

COMPETITION

The top 10 producers of copper comprise approximately 50 percent of total worldwide mined copper production. We currently rank second among those producers, with approximately eight percent of total worldwide estimated mined copper production. Our competitive position is based on the size, quality and grade of our ore bodies and our ability to manage costs compared with other producers. We have a diverse portfolio of mining operations with varying ore grades and cost structures. Our costs are driven by the location, grade and nature of our ore bodies and the level of input costs, including energy, labor and equipment. The metals markets are cyclical and our ability to maintain our competitive position over the long term is based on our ability to acquire and develop quality deposits, hire and retain a skilled workforce and to manage our costs.

Within the oil and gas industry, our competitors include national and international oil companies, major integrated oil and gas companies, numerous independent oil and gas companies and others. There is substantial competition in the oil and gas industry. Our ability to identify and successfully develop additional prospects and to discover oil and gas reserves in the future will depend on our ability to evaluate and select suitable properties, consummate transactions and manage our operations in a cost-efficient and effective manner in a highly competitive environment.

MINING OPERATIONS

Following are maps and descriptions of our mining operations in North America (including both copper and molybdenum operations), South America, Indonesia and Africa.

North America

In the U.S., most of the land occupied by our copper and molybdenum mines, concentrators, SX/EW facilities, smelter, refinery, rod mills, molybdenum roasters and processing facilities is generally owned by us or is located on unpatented mining claims owned by us. Certain portions of our Bagdad, Sierrita, Miami, Chino, Tyrone, Henderson and Climax operations are located on government-owned land and are operated under a Mine Plan of Operations or other use permit. Various federal and state permits or leases on government land are held for purposes incidental to mine operations.

Morenci

We own an 85 percent undivided interest in Morenci, with the remaining 15 percent owned by affiliates of Sumitomo Corporation. Each partner takes in kind its share of Morenci's production.

7

Table of Contents

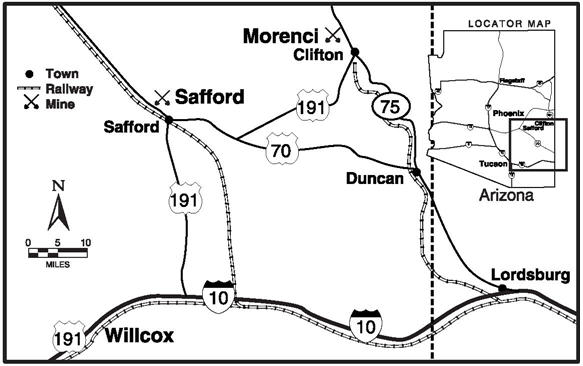

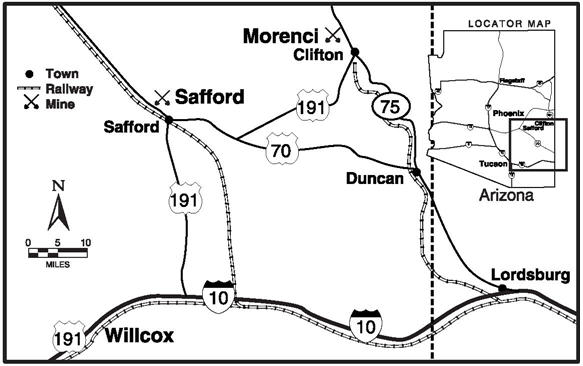

Morenci is an open-pit copper mining complex that has been in continuous operation since 1939 and previously was mined through underground workings. Morenci is located in Greenlee County, Arizona, approximately 50 miles northeast of Safford on U.S. Highway 191. The site is accessible by a paved highway and a railway spur.

The Morenci mine is a porphyry copper deposit that has oxide and secondary sulfide mineralization, and primary sulfide mineralization. The predominant oxide copper mineral is chrysocolla. Chalcocite is the most important secondary copper sulfide mineral with chalcopyrite as the dominant primary copper sulfide.

The Morenci operation consists of a 50,000 metric ton-per-day concentrator, that produces copper and molybdenum concentrates; a 68,000 metric ton-per-day crushed-ore leach pad and stacking system; a low-grade run-of-mine (ROM) leaching system; four SX plants; and three EW tank houses that produce copper cathode. Total EW tank house capacity is approximately 900 million pounds of copper per year. Morenci's concentrate leach, direct-electrowinning facility was commissioned in 2007 and processed copper concentrate until early 2009 when it was placed on care-and-maintenance status. The available mining fleet consists of one hundred and seven 236-metric ton haul trucks loaded by 12 shovels with bucket sizes ranging from 47 to 57 cubic meters, which are capable of moving an average of 815,000 metric tons of material per day.

Morenci's production, including our joint venture partner's share, totaled 664 million pounds of copper and 2 million pounds of molybdenum in 2013 , 632 million pounds of copper and 3 million pounds of molybdenum in 2012 , and 614 million pounds of copper and 2 million pounds of molybdenum in 2011 .

Morenci is expanding mining and milling capacity to process additional sulfide ores identified through exploratory drilling. The project is targeting incremental annual production (net of our joint venture partner's share) of approximately 225 million pounds of copper beginning in 2014 through an increase in milling rates from 50,000 metric tons of ore per day to approximately 115,000 metric tons of ore per day. Refer to "Mining Development Projects and Exploration" for further discussion.

Morenci is located in a desert environment with rainfall averaging 13 inches per year. The highest bench elevation is 2,000 meters above sea level and the ultimate pit bottom is expected to have an elevation of 840 meters above sea level. The Morenci operation encompasses approximately 64,750 acres, comprising 50,800 acres of patented mining claims and other fee lands, 10,900 acres of unpatented mining claims and 3,050 acres of land held by state or federal permits, easements and rights-of-way.

The Morenci operation's electrical power is primarily sourced from Tucson Electric Power Company, Arizona Public Service Company and the Luna Energy facility (in which we own a one-third interest) in Deming, New Mexico. Although we believe the Morenci operation has sufficient water sources to support current operations, we are a party to litigation that may impact our water rights claims or rights to continued use of currently available water supplies, which could adversely affect our water supply for the Morenci operation. Refer to Item 1A. "Risk Factors" and Item 3. "Legal Proceedings" for further discussion.

Bagdad

Our wholly owned Bagdad mine is an open-pit copper and molybdenum mining complex located in Yavapai County in west-central Arizona. It is approximately 60 miles west of Prescott and 100 miles northwest of Phoenix. The property can be reached by Arizona Highway 96, which ends at the town of Bagdad. The closest railroad is at

8

Table of Contents

Hillside, Arizona, approximately 24 miles southeast on Arizona Highway 96. The open-pit mining operation has been ongoing since 1945, and prior mining was conducted through underground workings.

The Bagdad mine is a porphyry copper deposit containing both sulfide and oxide mineralization. Chalcopyrite and molybdenite are the dominant primary sulfides and are the primary economic minerals in the mine. Chalcocite is the most common secondary copper sulfide mineral, and the predominant oxide copper minerals are chrysocolla, malachite and azurite.

The Bagdad operation consists of a 75,000 metric ton-per-day concentrator that produces copper and molybdenum concentrates, an SX/EW plant that can produce up to 25 million pounds per year of copper cathode from solution generated by low-grade stockpile leaching, and a pressure leach plant to process molybdenum concentrates. The available mining fleet consists of thirty 235-metric ton haul trucks loaded by five shovels with bucket sizes ranging from 44 to 62 cubic meters, which are capable of moving an average of 200,000 metric tons of material per day.

Bagdad's production totaled 216 million pounds of copper and 8 million pounds of molybdenum in 2013 , 197 million pounds of copper and 10 million pounds of molybdenum in 2012 , and 194 million pounds of copper and 10 million pounds of molybdenum in 2011 .

Bagdad is located in a desert environment with rainfall averaging 15 inches per year. The highest bench elevation is 1,200 meters above sea level and the ultimate pit bottom is expected to be 310 meters above sea level. The Bagdad operation encompasses approximately 21,750 acres, comprising 21,150 acres of patented mining claims and other fee lands and 600 acres of unpatented mining claims.

Bagdad receives electrical power from Arizona Public Service Company. Although we believe the Bagdad operation has sufficient water sources to support current operations, we are a party to litigation that may set legal precedents, which could adversely affect our water rights at Bagdad and at our other properties in Arizona. Refer to Item 1A. "Risk Factors" and Item 3. "Legal Proceedings" for further discussion.

Safford

Our wholly owned Safford mine has been in operation since 2007 and is an open-pit copper mining complex located in Graham County, Arizona, approximately eight miles north of the town of Safford and 170 miles east of Phoenix. The site is accessible by paved county road off U.S. Highway 70.

The Safford mine includes two copper deposits that have oxide mineralization overlaying primary copper sulfide mineralization. The predominant oxide copper minerals are chrysocolla and copper-bearing iron oxides with the predominant copper sulfide material being chalcopyrite.

The property is a mine-for-leach project and produces copper cathodes. The operation consists of two open pits feeding a crushing facility with a capacity of 103,000 metric tons per day. The crushed ore is delivered to leach pads by a series of overland and portable conveyors. Leach solutions feed a SX/EW facility with a capacity of 240 million pounds of copper per year. A sulphur burner plant is also in operation at Safford, providing a cost-effective source of sulphuric acid used in SX/EW operations. The available mining fleet consists of twenty 235-metric ton haul trucks loaded by four shovels with bucket sizes ranging from 31 to 34 cubic meters, which are capable of moving an average of 225,000 metric tons of material per day.

9

Table of Contents

Safford's copper production totaled 146 million pounds in 2013 , 175 million pounds in 2012 and 151 million pounds in 2011 .

Safford is located in a desert environment with rainfall averaging 10 inches per year. The highest bench elevation is 1,250 meters above sea level and the ultimate pit bottom is expected to have an elevation of 750 meters above sea level. The Safford operation encompasses approximately 25,000 acres, comprising 21,000 acres of patented lands, 3,950 acres of unpatented lands and 50 acres of land held by federal permit.

The Safford operation's electrical power is primarily sourced from Tucson Electric Power Company, Arizona Public Service Company and the Luna Energy facility. Although we believe the Safford operation has sufficient water sources to support current operations, we are a party to litigation that may impact our water right claims or rights to continued use of currently available water supplies, which could adversely affect our water supply for the Safford operation. Refer to Item 1A. "Risk Factors" and Item 3. "Legal Proceedings" for further discussion.

Sierrita

Our wholly owned Sierrita mine has been in operation since 1959 and is an open-pit copper and molybdenum mining complex located in Pima County, Arizona, approximately 20 miles southwest of Tucson and seven miles west of the town of Green Valley and Interstate Highway 19. The site is accessible by a paved highway and by rail.

The Sierrita mine is a porphyry copper deposit that has oxide and secondary sulfide mineralization, and primary sulfide mineralization. The predominant oxide copper minerals are malachite, azurite and chrysocolla. Chalcocite is the most important secondary copper sulfide mineral, and chalcopyrite and molybdenite are the dominant primary sulfides.

The Sierrita operation includes a 102,000 metric ton-per-day concentrator that produces copper and molybdenum concentrates. Sierrita also produces copper from a ROM oxide-leaching system. Cathode copper is plated at the Twin Buttes EW facility, which has a design capacity of approximately 50 million pounds of copper per year. The Sierrita operation also has a copper sulfate crystal plant, which has the capacity to produce 40 million pounds of copper sulfate per year, and molybdenum facilities consisting of a leaching circuit, two molybdenum roasters and a packaging facility. The molybdenum facilities process molybdenum concentrate produced by Sierrita, from our other mines and from third-party sources. The available mining fleet consists of twenty-five 235-metric ton haul trucks loaded by four shovels with bucket sizes ranging from 34 to 56 cubic meters, which are capable of moving an average of 200,000 metric tons of material per day.

Sierrita's production totaled 171 million pounds of copper and 20 million pounds of molybdenum in 2013 , 157 million pounds of copper and 21 million pounds of molybdenum in 2012 , and 177 million pounds of copper and 23 million pounds of molybdenum in 2011 .

Sierrita is located in a desert environment with rainfall averaging 12 inches per year. The highest bench elevation is 1,160 meters above sea level and the ultimate pit bottom is expected to be 440 meters above sea level. The Sierrita operation, including the adjacent Twin Buttes site (refer to "Smelting Facilities and Other Mining Properties" for further discussion), encompasses approximately 37,650 acres, comprising 13,300 acres of patented mining claims and 24,350 acres of split-estate lands.

10

Table of Contents

Sierrita receives electrical power through long-term contracts with the Tucson Electric Power Company. Although we believe the Sierrita operation has sufficient water sources to support current operations, we are a party to litigation that may impact our water rights claims or rights to continued use of currently available water supplies, which could adversely affect our water supply for the Sierrita operation. Refer to Item 1A. "Risk Factors" and Item 3. "Legal Proceedings" for further discussion.

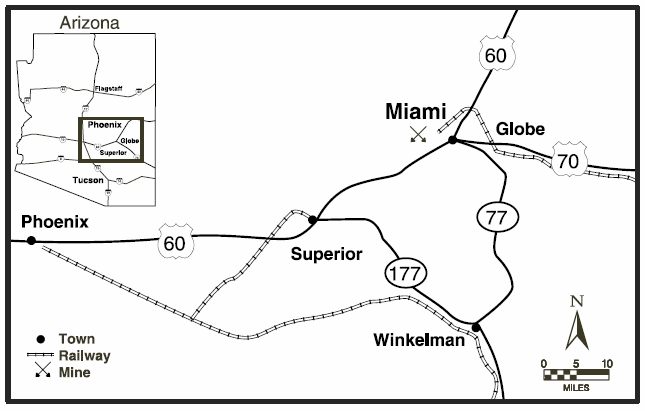

Miami

Our wholly owned Miami mine is an open-pit copper mining complex located in Gila County, Arizona, approximately 90 miles east of Phoenix and six miles west of the city of Globe on U.S. Highway 60. The site is accessible by a paved highway and by rail.

The Miami mine is a porphyry copper deposit that has leachable oxide and secondary sulfide mineralization. The predominant oxide copper minerals are chrysocolla, copper-bearing clays, malachite and azurite. Chalcocite and covellite are the most important secondary copper sulfide minerals.

Since about 1915, the Miami mining operation had processed copper ore using both flotation and leaching technologies. Current operations include leaching by the SX/EW process. The design capacity of the SX/EW plant is 200 million pounds of copper per year. The available mining fleet consists of twelve 227-metric ton haul trucks loaded by three shovels with bucket sizes ranging from 31 to 34 cubic meters, which are capable of moving an average of 95,000 metric tons of material per day.

Miami's copper production totaled 61 million pounds in 2013 and 66 million pounds in both 2012 and 2011 .

Miami is located in a desert environment with rainfall averaging 18 inches per year. The highest bench elevation is 1,390 meters above sea level, and the ultimate pit bottom will have an elevation of 810 meters above sea level. The Miami operation encompasses approximately 9,100 acres, comprising 8,750 acres of patented mining claims and other fee lands and 350 acres of unpatented mining claims.

Miami receives electrical power through long-term contracts with the Salt River Project and natural gas through long-term contracts with El Paso Natural Gas as the transporter. Although we believe the Miami operation has sufficient water sources to support current operations, we are a party to litigation that may impact our water right claims or rights to continued use of currently available water supplies, which could adversely affect our water supply for the Miami operation. Refer to Item 1A. "Risk Factors" and Item 3. "Legal Proceedings" for further discussion.

11

Table of Contents

Chino and Tyrone

Chino

Our wholly owned Chino mine is an open-pit copper mining complex located in southwestern New Mexico in Grant County, approximately 15 miles east of the town of Silver City off of State Highway 180. The mine is accessible by paved roads and by rail. Chino has been in operation since 1910.

The Chino mine is a porphyry copper deposit with adjacent copper skarn deposits. There is leachable oxide and secondary sulfide mineralization, and millable primary sulfide mineralization. The predominant oxide copper minerals are chrysocolla and azurite. Chalcocite is the most important secondary copper sulfide mineral, and chalcopyrite and molybdenite the dominant primary sulfides.

The Chino operation consists of a 36,000 metric ton-per-day concentrator that produces copper and molybdenum concentrates, and a 150 million pound-per-year SX/EW plant that produces copper cathode from solution generated by ROM leaching. The available mining fleet consists of thirty-five 240-metric ton haul trucks loaded by four shovels with bucket sizes ranging from 42 to 48 cubic meters, which are capable of moving an average of 220,000 metric tons of material per day.

Ramp up activities at Chino are continuing, with production of approximately 250 million pounds of copper per year targeted in 2014. Chino's production totaled 171 million pounds of copper and 2 million pounds of molybdenum in 2013 , 144 million pounds of copper and 2 million pounds of molybdenum in 2012 , and 69 million pounds of copper in 2011 .

Chino is located in a desert environment with rainfall averaging 16 inches per year. The highest bench elevation is 2,250 meters above sea level, and the ultimate pit bottom is expected to be 1,500 meters above sea level. The Chino operation encompasses approximately 118,600 acres, comprising 113,200 acres of patented mining claims and other fee lands and 5,400 acres of unpatented mining claims.

Chino receives power from the Luna Energy facility and from the open market. We believe Chino has sufficient water resources to support current operations.

Tyrone

Our wholly owned Tyrone mine is an open-pit copper mining complex which has been in operation since 1967. It is located in southwestern New Mexico in Grant County, approximately 10 miles south of Silver City, New Mexico, along State Highway 90. The site is accessible by paved road and rail.

The Tyrone mine is a porphyry copper deposit. Mineralization is predominantly secondary sulfide consisting of chalcocite with leachable oxide mineralization consisting of chrysocolla.

Copper processing facilities consist of a SX/EW operation with a maximum capacity of approximately 100 million pounds of copper cathodes per year. The available mining fleet consists of nineteen 240-metric ton haul trucks loaded by three shovels with bucket sizes ranging from 17 to 47 cubic meters, which are capable of moving an average of 135,000 metric tons of material per day.

Tyrone's copper production totaled 96 million pounds in 2013 , 83 million pounds in 2012 and 76 million pounds in 2011 .

12

Table of Contents

Tyrone is located in a desert environment with rainfall averaging 16 inches per year. The highest bench elevation is 2,000 meters above sea level and the ultimate pit bottom is expected to have an elevation of 1,500 meters above sea level. The Tyrone operation encompasses approximately 35,200 acres, comprising 18,750 acres of patented mining claims and other fee lands and 16,450 acres of unpatented mining claims.

Tyrone receives electrical power from the Luna Energy facility and from the open market. We believe the Tyrone operation has sufficient water resources to support current operations.

Henderson and Climax

Henderson

Our wholly owned Henderson molybdenum mine has been in operation since 1976 and is located approximately 42 miles west of Denver, Colorado, off U.S. Highway 40. Nearby communities include the towns of Empire, Georgetown and Idaho Springs. The Henderson mill site is located approximately 15 miles west of the mine and is accessible from Colorado State Highway 9. The Henderson mine and mill are connected by a 10-mile conveyor tunnel under the Continental Divide and an additional five-mile surface conveyor. The tunnel portal is located five miles east of the mill.

The Henderson mine is a porphyry molybdenum deposit with molybdenite as the primary sulfide mineral.

The Henderson operation consists of a large block-cave underground mining complex feeding a concentrator with a current capacity of approximately 32,000 metric tons per day. Henderson has the capacity to produce approximately 40 million pounds of molybdenum per year. The majority of the molybdenum concentrate produced is shipped to our Fort Madison, Iowa, processing facility. The available underground mining equipment fleet consists of fourteen 9-metric ton load-haul-dump (LHD) units and six 73-metric ton haul trucks, which deliver ore to a gyratory crusher feeding a series of three overland conveyors to the mill stockpiles.

Henderson's molybdenum production totaled 30 million pounds in 2013 , 34 million pounds in 2012 and 38 million pounds in 2011 .

The Henderson mine is located in a mountainous region with the main access shaft at 3,180 meters above sea level. The main production levels are currently at elevations of 2,200 and 2,350 meters above sea level. This region experiences significant snowfall during the winter months.

The Henderson mine and mill operations encompass approximately 11,900 acres, comprising 11,850 acres of patented mining claims and other fee lands and a 50-acre easement with the U.S. Forest Service for the surface portion of the conveyor corridor.

Henderson operations receive electrical power through long-term contracts with Xcel Energy and natural gas through long-term contracts with BP Energy Company (with Xcel Energy as the transporter). We believe the Henderson operation has sufficient water resources to support current operations.

Climax

Our wholly owned Climax mine is located 13 miles northeast of Leadville, Colorado, off Colorado State Highway 91 at the top of Fremont Pass. The mine is accessible by paved roads .

13

Table of Contents

The Climax ore body is a porphyry molybdenum deposit with molybdenite as the primary sulfide mineral.

The Climax open-pit mine was commissioned in second-quarter 2012 and includes a 25,000 metric ton-per-day mill facility. The available mining fleet consists of nine 177-metric ton haul trucks loaded by two hydraulic shovels with bucket sizes of 34 cubic meters, which are capable of moving an average of 90,000 metric tons of material per day.

Molybdenum production from Climax totaled 19 million pounds in 2013 and 7 million pounds in 2012 (reflecting production since the start of commercial operations in May 2012).

The Climax mine is located in a mountainous region with snowfall averaging 23 feet per year. The highest bench elevation is approximately 4,050 meters above sea level, and the ultimate pit bottom is expected to have an elevation of approximately 3,100 meters above sea level. The operations encompass approximately 14,350 acres, consisting primarily of patented mining claims and other fee lands.

Climax operations receive electrical power through long-term contracts with Xcel Energy and natural gas through long-term contracts with BP Energy Company (with Xcel Energy as the transporter). We believe the Climax operation has sufficient water resources to support current operations.

South America

At our operations in South America, mine properties and facilities are controlled through mining claims or concessions under the general mining laws of the relevant country. The claims or concessions are owned or controlled by the operating companies in which we or our subsidiaries have a controlling ownership interest. Roads, power lines and aqueducts are controlled by easements.

Cerro Verde

We have a 53.56 percent ownership interest in Cerro Verde, with the remaining 46.44 percent held by SMM Cerro Verde Netherlands B.V. (21.0 percent), Compañia de Minas Buenaventura S.A.A. (19.58 percent) and other stockholders whose shares are publicly traded on the Lima Stock Exchange (5.86 percent).

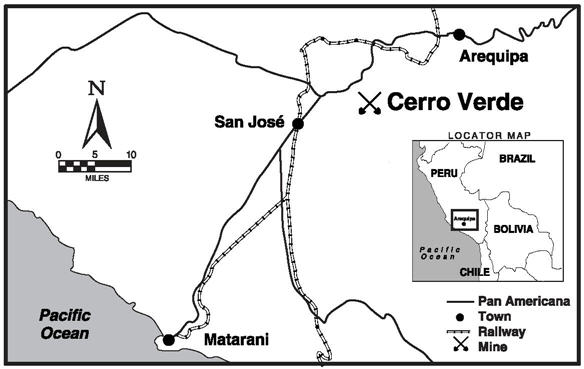

Cerro Verde is an open-pit copper and molybdenum mining complex that has been in operation since 1976 and is located 20 miles southwest of Arequipa, Peru. The site is accessible by paved highway. A majority of Cerro Verde's copper cathode production is sold locally and the remaining copper cathodes and concentrate production are transported approximately 70 miles by truck and rail to the Port of Matarani for shipment to international markets.

The Cerro Verde mine is a porphyry copper deposit that has oxide and secondary sulfide mineralization, and primary sulfide mineralization. The predominant oxide copper minerals are brochantite, chrysocolla, malachite and copper "pitch." Chalcocite and covellite are the most important secondary copper sulfide minerals. Chalcopyrite and molybdenite are the dominant primary sulfides.

Cerro Verde's current operation consists of an open-pit copper mine, a 120,000 metric ton-per-day concentrator and SX/EW leaching facilities. Leach copper production is derived from a 39,000 metric ton-per-day crushed leach facility and a ROM leach system. This leaching operation has a capacity of approximately 200 million pounds of copper per year. The available fleet consists of forty-two 230-metric ton haul trucks loaded by four electric shovels with bucket sizes ranging in size from 33 to 53 cubic meters and one hydraulic shovel with a bucket size of 21 cubic meters, which are capable of moving an average of 335,000 metric tons of material per day.

14

Table of Contents

Cerro Verde's production totaled 558 million pounds of copper and 13 million pounds of molybdenum in 2013 , 595 million pounds of copper and 8 million pounds of molybdenum in 2012 , and 647 million pounds of copper and 10 million pounds of molybdenum in 2011 .

Construction activities associated with a large-scale expansion at Cerro Verde are in progress, which are expected to expand the concentrator facilities to 360,000 metric tons of ore per day and provide incremental annual production of approximately 600 million pounds of copper and 15 million pounds of molybdenum beginning in 2016. Refer to "Mining Development Projects and Exploration" for further discussion.

Cerro Verde is located in a desert environment with rainfall averaging 1.5 inches per year and is in an active seismic zone. The highest bench elevation is 2,753 meters above sea level and the ultimate pit bottom is expected to be 1,568 meters above sea level. The Peruvian general mining law and Cerro Verde's mining stability agreement grants the surface rights of mining concessions located on government land. Cerro Verde has a mining concession covering approximately 157,000 acres, including 14,500 acres rented from the Regional Government of Arequipa, plus 25 acres of owned property, and 80 acres of rights-of-way outside the mining concession area.

Cerro Verde receives electrical power under long-term contracts with Kallpa Generación SA and Empresa de Generación Eléctrica de Arequipa. Water for our Cerro Verde processing operations comes from renewable sources through a series of storage reservoirs on the Rio Chili watershed that collect water primarily from seasonal precipitation. Cerro Verde's participation in the Pillones Reservoir Project has secured water rights from the regulated system that we believe will be sufficient to support Cerro Verde's current operations.

An agreement has been reached with the Regional Government of Arequipa, the National Government, the local water utility company, Servicio de Agua Potable y Alcantarillado de Arequipa S.A. (SEDAPAR), and other local institutions to allow Cerro Verde to finance, engineer and construct a wastewater treatment plant for the city of Arequipa. Cerro Verde has obtained authorization to reuse an annual average of one cubic meter per second of the treated water, which would be used to supplement existing water supplies to support the concentrator expansion.

For further discussion of risks associated with the availability of water, see Item 1A. "Risk Factors."

El Abra

We own a 51 percent interest in El Abra, and the remaining 49 percent interest is held by the state-owned copper enterprise Corporación Nacional del Cobre de Chile (CODELCO).

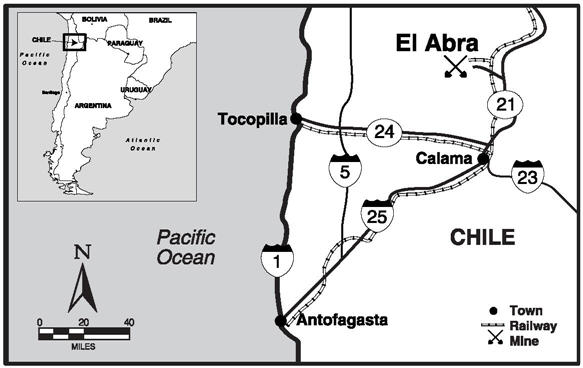

El Abra is an open-pit copper mining complex that has been in operation since 1996 and is located 47 miles north of Calama in Chile's El Loa province, Region II. The site is accessible by paved highway and by rail.

The El Abra mine is a porphyry copper deposit that has sulfide and oxide mineralization. The predominant primary sulfide copper minerals are bornite and chalcopyrite. There is a minor amount of secondary sulfide mineralization

as chalcocite. The oxide copper minerals are chrysocolla and pseudomalachite. There are lesser amounts of copper-bearing clays and tenorite.

The El Abra operation consists of an open-pit copper mine and a SX/EW facility with a capacity of 500 million pounds of copper cathode per year from a 125,000 metric ton-per-day crushed leach circuit and a similar-sized

15

Table of Contents

ROM leaching operation. The available fleet consists of forty-one 220-metric ton haul trucks loaded by four shovels with buckets ranging in size from 26 to 41 cubic meters, which are capable of moving an average of 223,000 metric tons of material per day.

El Abra's copper production totaled 343 million pounds in 2013 , 338 million pounds in 2012 and 274 million pounds in 2011 .

We continue to evaluate a potential large-scale milling operation at El Abra to process additional sulfide material and to achieve higher recoveries. Refer to "Mining Development Projects and Exploration" for further discussion.

El Abra is located in a desert environment with rainfall averaging less than one inch per year and is in an active seismic zone. The highest bench elevation is 4,180 meters above sea level and the ultimate pit bottom is expected to be 3,430 meters above sea level. El Abra controls a total of approximately 151,300 acres of mining claims covering the ore deposit, stockpiles, process plant, and water wellfield and pipeline. In addition, El Abra has land surface rights for the road between the processing plant and the mine, the water wellfield, power transmission lines and for the water pipeline from the Salar de Ascotán aquifer.

El Abra currently receives electrical power under a long-term contract with Electroandina. Water for our El Abra processing operations comes from pumping of groundwater from the Salar de Ascotán aquifer pursuant to regulatory approval. We believe El Abra has sufficient water rights to support current operations. For a discussion of risks associated with the availability of water, see Item 1A. "Risk Factors."

Candelaria and Ojos del Salado

Candelaria

We have an 80 percent ownership interest in Candelaria, with the remaining 20 percent interest owned by affiliates of Sumitomo Corporation.

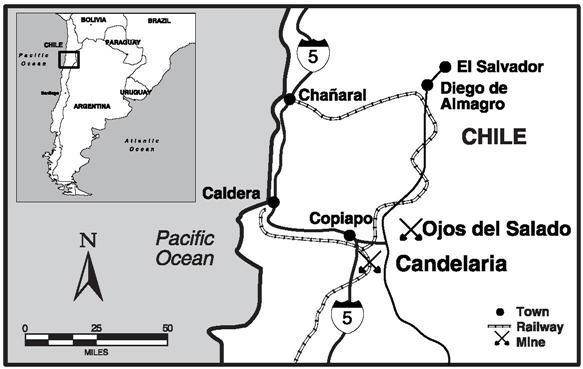

Candelaria's open-pit copper mine has been in operation since 1993 and the underground mine has been in operation since 2005. The Candelaria copper mining complex is located approximately 12 miles south of Copiapó in northern Chile's Atacama province, Region III. The site is accessible by two maintained dirt roads, one coming through the Tierra Amarilla community and the other off of Route 5 of the International Pan-American Highway. Copper concentrates are transported by truck to the Punta Padrones port facility located in Caldera, approximately 50 miles northwest of the mine.

The Candelaria mine is an iron oxide, copper and gold deposit. Primary sulfide mineralization consists of chalcopyrite.

The Candelaria operation consists of an open-pit copper mine and a 6,000 metric ton-per-day underground copper mine, which is mined by sublevel stoping, feeding a 75,000 metric ton-per-day concentrator. The available fleet consists of forty-eight 225-metric ton haul trucks loaded by six shovels with bucket sizes ranging from 28 to 43 cubic meters, which are capable of moving an average of 250,000 metric tons of material per day.

Candelaria's production totaled 370 million pounds of copper and 87 thousand ounces of gold in 2013 , 271 million pounds of copper and 69 thousand ounces of gold in 2012 , and 327 million pounds of copper and 85 thousand ounces of gold in 2011 .

16

Table of Contents

Candelaria is located in a desert environment with rainfall averaging less than one inch per year and is in an active seismic zone. The highest bench elevation is 832 meters above sea level and the ultimate pit bottom is expected to be 80 meters below sea level. The Candelaria property encompasses approximately 13,400 acres, including approximately 125 acres for the port facility in Caldera.

Candelaria receives electrical power through long-term contracts with AES Gener S.A., a local energy company. Candelaria's water supply comes from a nearby wastewater treatment facility and our desalination plant and pipeline that was completed in 2013. We believe that both of these sources will supply Candelaria's long term water needs.

Ojos del Salado

We have an 80 percent ownership interest in Ojos del Salado, with the remaining 20 percent interest owned by affiliates of Sumitomo Corporation.

The Ojos del Salado operation began commercial production in 1929 and consists of two underground copper mines (Santos and Alcaparrosa) and a 3,800 metric ton-per-day concentrator. The operation is located approximately 10 miles east of Copiapó in northern Chile's Atacama province, Region III, and is accessible by paved highway. The Ojos del Salado mines are iron oxide and copper and gold deposits. Primary sulfide mineralization consists of chalcopyrite.

The Ojos del Salado operation has a capacity of 3,800 metric tons per day of ore from the Santos underground mine and 4,000 metric tons of ore per day from the Alcaparrosa underground mine. The ore from both mines is mined by sublevel stoping since both the ore and enclosing rocks are competent. The broken ore is removed from the stopes using scoops and loaded into an available fleet of twenty-six 28-metric ton trucks, which transport the ore to the surface. The ore from the Santos mine is hauled directly to the Ojos del Salado mill for processing, and the ore from the Alcaparrosa mine is reloaded into six 54-metric ton trucks and hauled seven miles to the Candelaria mill for processing. The Ojos del Salado concentrator has the capacity to produce over 30 million pounds of copper and 9 thousand ounces of gold per year. Tailings from the Ojos del Salado mill are pumped to the Candelaria tailings facility for final deposition. The Candelaria facility has sufficient capacity for the remaining Ojos del Salado tailings.

Ojos del Salado's production totaled 52 million pounds of copper and 14 thousand ounces of gold in 2013 , 53 million pounds of copper and 14 thousand ounces of gold in 2012 , and 58 million pounds of copper and 16 thousand ounces of gold in 2011 .

Ojos del Salado is located in a desert environment with rainfall averaging less than one inch per year and is in an active seismic zone. The highest underground level is at an elevation of 530 meters above sea level, with the lowest underground level at 40 meters above sea level. The Ojos del Salado mineral rights encompass approximately 15,800 acres, which includes 6,800 acres of owned land in and around the Ojos del

Salado underground mines and plant site.

Ojos del Salado receives electrical power through long-term contracts with AES Gener S.A. Ojos del Salado's water supply comes from a nearby wastewater treatment facility and our desalination plant and pipeline that was completed in 2013. We believe that both of these sources will supply Ojos del Salado's long term water needs.

17

Table of Contents

Indonesia

Ownership . PT-FI is a limited liability company organized under the laws of the Republic of Indonesia and incorporated in Delaware. We directly own 81.28 percent of the outstanding common stock of PT-FI and indirectly own 9.36 percent through our wholly owned subsidiary, PT Indocopper Investama; the Indonesian government owns the remaining 9.36 percent.

We have established certain unincorporated joint ventures with Rio Tinto plc (Rio Tinto), under which Rio Tinto has a 40 percent interest in certain assets and future production exceeding specified annual amounts of copper, gold and silver. Refer to Note 3 for further discussion of our joint ventures with Rio Tinto.

We also conducted exploration activities in Papua, Indonesia through two other entities: PT Nabire Bakti Mining (PTNBM) and PT Irja Eastern Minerals (Eastern Minerals), of which we own 100 percent. As further discussed below, we have begun the process to terminate the Contracts of Work (COW) for PTNBM and Eastern Minerals and to return the exploration areas to the Indonesian government.

Contracts of Work . PT-FI conducts its current exploration and mining operations in Indonesia through a COW with the Indonesian government. The COW governs our rights and obligations relating to taxes, exchange controls, royalties, repatriation and other matters, and was concluded pursuant to the 1967 Foreign Capital Investment Law, which expresses Indonesia's foreign investment policy and provides basic guarantees of remittance rights and protection against nationalization, a framework for economic incentives and basic rules regarding other rights and obligations of foreign investors. Specifically, the COW provides that the Indonesian government will not nationalize or expropriate PT-FI's mining operations. Any disputes regarding the provisions of the COW are subject to international arbitration; however, we have not had an arbitration during the more than 40 years we have operated in Indonesia.

PT-FI's original COW was entered into in 1967 and was replaced by a new COW in 1991. The initial term of the current COW expires in 2021, but can be extended for two 10-year periods subject to Indonesian government approval, which pursuant to the COW cannot be withheld or delayed unreasonably. The COW allows us to conduct exploration, mining and production activities in the 24,700-acre Block A area, which is where all of PT-FI's proven and probable mineral reserves and current mining operations are located. Under the COW, PT-FI also conducts exploration activities in the Block B area. We expect the Block B area to be reduced to approximately 413,000 acres once the Department of Energy and Mineral Resources (DEMR) formally accepts PT-FI's relinquishment of approximately 89,000 acres, and further relinquishments may result from the COW evaluation process discussed in Note 13 .

18

Table of Contents

PT-FI pays royalties on copper, gold and silver under its COW, and has agreed to pay additional royalties to the Indonesian government that are not required under its COW. The additional royalties provide further support to the local governments and to the people of the Indonesian province of Papua. PT-FI's share of the combined royalties totaled $109 million in 2013 , $93 million in 2012 and $137 million in 2011 .

Under a joint venture agreement through PTNBM, we were allowed to conduct exploration activities under a separate COW on three parcels contiguous to PT-FI's Block B and one of Eastern Minerals' blocks. Since 2011, we have made a number of requests of the DEMR, including suspension of activities for the COW, while awaiting receipt of permits from the Indonesian government's Department of Forestry that would allow us to resume exploration activities. In September 2013, we received notification from the DEMR advising us to lodge a completed feasibility study within 30 days and enter into the construction period within the COW timeline. However, since we had not completed our exploration program, we were unable to comply. The letter was in effect, a denial of our previously unanswered requests, resulting in a decision to terminate the COW. We have initiated actions required under the COW that will result in its formal termination.

Eastern Minerals is allowed to conduct exploration in Papua through a joint venture agreement under a separate COW. The situation with the Eastern Minerals COW is similar to that of PTNBM, and we expect to receive a similar response from the DEMR. Because of this expected outcome, we have notified the DEMR of our intentions to terminate the COW and have initiated the formal termination process.

In 2009, Indonesia enacted a mining law (2009 Mining Law), which operates under a licensing system that is significantly less protective of licensees than the contract of work system that governs PT-FI, Eastern Minerals and PTNBM. The 2009 Mining Law and the regulations issued pursuant to that law provide that contracts of work would continue to be honored until their expiration. However, the regulations, including those issued in January 2014, attempt to apply certain provisions of the 2009 Mining Law and regulations to existing contracts of work and seek to apply the licensing system to any extension periods of contracts of work.

In January 2012, the President of Indonesia issued a decree calling for the creation of a team of Ministers to evaluate contracts of work for adjustment to the 2009 Mining Law and to take steps to assess and determine the Indonesian government's position on reduction to the size of contract concessions, increasing government revenues and domestic processing of minerals. We have been engaged in discussions with officials of the Indonesian government to complete this evaluation process and obtain an extension of the PT-FI COW beyond its primary term ending in 2021 to 2041, as provided under the terms of the COW, which can only be modified by mutual agreement between PT-FI and the Indonesian government. Refer to Item 1A. "Risk Factors" for further discussion.

In January 2014, the Indonesian government published regulations providing that holders of contracts of work with existing processing facilities in Indonesia may continue to export product through January 12, 2017, but established new requirements for the continued export of copper concentrates, including the imposition of a progressive export duty on copper concentrates in the amount of 25 percent in 2014, rising to 60 percent by mid-2016. PT-FI's COW authorizes it to export concentrates and specifies the taxes and other fiscal terms available to its operations. The COW states that PT-FI shall not be subject to taxes, duties or fees subsequently imposed or approved by the Indonesian government except as expressly provided in the COW. Additionally, PT-FI complied with the requirements of its COW for local processing by arranging for the construction and commissioning of Indonesia's only copper smelter and refinery, which is owned and operated by PT Smelting (refer to "Smelting Facilities and Other Mining Properties").

The January 2014 regulations conflict with PT-FI's contractual rights under its COW. We are working with the Indonesian government to clarify the situation and to defend PT-FI's rights under its COW. PT-FI is also seeking to obtain the required administrative permits for 2014 exports, which have been delayed as a result of the new regulations.

As of February 21, 2014, PT-FI has not obtained administrative approval for 2014 exports. PT-FI has implemented near-term changes to its operations to coordinate its concentrate production with PT Smelting's operating plans. Since mid-January 2014, PT-FI's milling rate has averaged approximately 112,000 metric tons of ore per day, which is approximately half of normal rates. PT-FI is engaging with the government of Indonesia to reach a resolution that would enable PT-FI to resume normal operations as soon as possible. In the event that PT-FI is unable to resume normal operations for an extended period, we plan to consider further actions, including constraining operating

19

Table of Contents

costs, deferring capital expenditures and implementing workforce reductions. PT-FI may also be required to declare force majeure under its concentrate sales agreements.

Grasberg Minerals District . PT-FI operates in the remote highlands of the Sudirman Mountain Range in the province of Papua, Indonesia, which is on the western half of the island of New Guinea. We and our predecessors have been the only operator of exploration and mining activities in Block A since 1967.

The Grasberg minerals district has three operating mines: the Grasberg open pit, the Deep Ore Zone (DOZ) underground mine and the Big Gossan underground mine. We also have several projects in progress in the Grasberg minerals district related to the development of the large-scale, long-lived, high-grade underground ore bodies located beneath and nearby the Grasberg open pit. In aggregate, these underground ore bodies are expected to ramp up over several years to produce approximately 240,000 metric tons of ore per day following the transition from the Grasberg open pit, currently anticipated to occur in 2017. Refer to "Mining Development Projects and Exploration" for further discussion.

PT-FI's production, including our joint venture partner's share, totaled 928 million pounds of copper and 1.14 million ounces of gold in 2013 , 695 million pounds of copper and 862 thousand ounces of gold in 2012 and 882 million pounds of copper and 1.44 million ounces of gold in 2011 .

Our principal source of power for all our Indonesian operations is a coal-fired power plant that we built in 1998. Diesel generators supply peaking and backup electrical power generating capacity. A combination of naturally occurring mountain streams and water derived from our underground operations provides water for our operations. Our Indonesian operations are in an active seismic zone and experience average annual rainfall of approximately 200 inches.

Grasberg Open Pit

We began open-pit mining of the Grasberg ore body in 1990, with mining operations expected to continue through early 2017. Production in the open pit is currently at the 3,190- to 3,940- meter elevation level and totaled 46 million metric tons of ore in 2013 , which provided 71 percent of PT-FI's 2013 mill feed.

The current open-pit equipment fleet consists of over 500 units. The larger mining equipment directly associated with production includes an available fleet of 157 haul trucks with payloads ranging from 218 to 330 metric tons and 16 shovels with bucket sizes ranging from 30 to 42 cubic meters, which mined an average of 381,000 metric tons of material per day during 2013 , 399,000 metric tons per day in 2012 and 486,000 metric tons per day in 2011 .

Grasberg crushing and conveying systems are integral to the mine and provide the capacity to transport up to 250,000 metric tons per day of Grasberg ore to the mill and 150,000 metric tons per day of overburden to the overburden stockpiles. The remaining overburden is moved by haul trucks.

DOZ underground mine

The DOZ ore body lies vertically below the now depleted Intermediate Ore Zone. We began production from the DOZ ore body in 1989 using open stope mining methods, but suspended production in 1991 in favor of production from the Grasberg open pit. Production resumed in September 2000 using the block-cave method and is at the 3,110-meter elevation level. Production from the DOZ mine averaged 49,400 metric tons of ore per day for the year 2013 and is expected to ramp up to the design rate of 80,000 metric tons of ore per day during 2014 pending approval of export permits as described above. Production at the DOZ mine is expected to continue through 2019.

The DOZ mine fleet consists of over 200 pieces of mobile heavy equipment, which is capable of mining an average of 80,000 metric tons of material per day. The primary mining equipment directly associated with production and development includes an available fleet of 44 LHD units and 20 haul trucks. Each production LHD unit typically carries approximately 11 metric tons of ore. Using ore passes and chutes, the LHD units transfer ore into 55-metric ton capacity haul trucks. The trucks dump into two gyratory crushers and the ore is then conveyed to the surface stockpiles for processing.

The success of the development of the DOZ mine, one of the world's largest underground mines, provides confidence in the future development of PT-FI's large-scale undeveloped underground ore bodies.

20

Table of Contents

Big Gossan underground mine

The Big Gossan mine lies underground and adjacent to the current mill site. It is a tabular, near vertical ore body with approximate dimensions of 1,200 meters along strike and 800 meters down dip with varying thicknesses from 20 meters to 120 meters. The mine utilizes a blasthole stoping method with delayed paste backfill. Stopes of varying sizes are mined and the ore dropped down passes to a truck haulage level. Trucks are chute loaded and transport the ore to a jaw crusher. The crushed ore is then hoisted vertically via a two-skip production shaft to a level where it is loaded onto a conveyor belt. The belt carries the ore to one of the main underground conveyors where the ore is transferred and conveyed to the surface stockpiles for processing.

The Big Gossan underground mine averaged 2,100 metric tons of ore per day for the year 2013 and is expected to ramp up to 7,000 metric tons of ore per day by 2016. Although development activities continue, production from the Big Gossan underground mine is currently suspended pending resolution of the export regulatory matter discussed above.

The Big Gossan underground mine fleet consists of over 70 pieces of mobile heavy equipment, which includes 11 loaders and eight trucks used in development and production activities.

Description of Ore Bodies . Our Indonesia ore bodies are located within and around two main igneous intrusions, the Grasberg monzodiorite and the Ertsberg diorite. The host rocks of these ore bodies include both carbonate and clastic rocks that form the ridge crests and upper flanks of the Sudirman Range, and the igneous rocks of monzonitic to dioritic composition that intrude them. The igneous-hosted ore bodies (the Grasberg open pit and block cave, and portions of the DOZ block cave) occur as vein stockworks and disseminations of copper sulfides, dominated by chalcopyrite and, to a lesser extent, bornite. The sedimentary-rock hosted ore bodies (portions of the DOZ and all of the Big Gossan) occur as "magnetite-rich, calcium/magnesian skarn" replacements, whose location and orientation are strongly influenced by major faults and by the chemistry of the carbonate rocks along the margins of the intrusions.

The copper mineralization in these skarn deposits is dominated by chalcopyrite, but higher bornite concentrations are common. Moreover, gold occurs in significant concentrations in all of the district's ore bodies, though rarely visible to the naked eye. These gold concentrations usually occur as inclusions within the copper sulfide minerals, though, in some deposits, these concentrations can also be strongly associated with pyrite.

The following diagram indicates the relative elevations (in meters) of our reported ore bodies.

21

Table of Contents

Africa

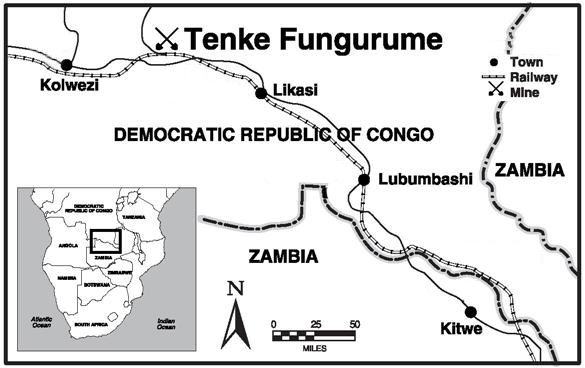

TFM is organized under the laws of the DRC. We own an effective 56 percent interest in TFM, with the remaining ownership interests held by Lundin Mining Corporation (Lundin) (an effective 24 percent interest) and La Générale des Carrières et des Mines (Gécamines), which is wholly owned by the DRC government (a 20 percent non-dilutable interest).

TFM is entitled to mine in the DRC under an Amended and Restated Mining Convention (ARMC) with the DRC government. The original Mining Convention was entered into in 1996 and was replaced with the ARMC in 2005, which was further amended in 2010 (approved in 2011). The current ARMC will remain in effect for as long as the Tenke concessions are exploitable.

TFM pays a royalty of two percent of net revenues under the ARMC, which totaled $29 million in 2013 , $25 million in 2012 and $24 million in 2011 .

22

Table of Contents