UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

Form 10-K

S ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d)

OF THE SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended December 31, 2009

OR

£ TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d)

OF THE SECURITIES EXCHANGE ACT OF 1934

For the transition period from to

Commission file number 1-8974

Honeywell International Inc.

(Exact name of registrant as specified in its charter)

|

|

|

DELAWARE | 22-2640650 | |

|

|

|

(State or other jurisdiction of | (I.R.S. Employer | |

101 Columbia Road | 07962 | |

|

|

|

(Address of principal executive offices) | (Zip Code) |

Registrant's telephone number, including area code (973) 455-2000

Securities registered pursuant to Section 12(b) of the Act:

|

|

|

Title of Each Class | Name of Each Exchange | |

|

|

|

Common Stock, par value $1 per share* | New York Stock Exchange | |

| Chicago Stock Exchange | |

9 1 / 2 % Debentures due June 1, 2016 | New York Stock Exchange |

| ||||||||||||||||||||

* |

| The common stock is also listed for trading on the London Stock Exchange.

| ||||||||||||||||||

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the Registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes S No £

Indicate by check mark if the Registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Exchange Act. Yes £ No S

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes S No £

Indicate by check mark whether the Registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes S No £

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of Registrant's knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. £

Indicate by check mark whether the Registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See definition of "accelerated filer," "large accelerated filer," and "smaller reporting company" in Rule 12b-2 of the Exchange Act. (Check One):

Large accelerated filer S Accelerated filer £ Non-accelerated filer £ Smaller reporting company £

Indicate by check mark whether the Registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes £ No S

The aggregate market value of the voting stock held by nonaffiliates of the Registrant was approximately $23.2 billion at June 30, 2009.

There were 764,552,212 shares of Common Stock outstanding at January 31, 2010.

Documents Incorporated by Reference

Part III: Proxy Statement for Annual Meeting of Shareowners to be held April 26, 2010.

TABLE OF CONTENTS

|

|

|

|

|

|

|

| Item |

| Page | |||

|

|

|

| |||

Part I. | 1. | Business | 1 | |||

| 1A. | Risk Factors | 11 | |||

| 1B. | Unresolved Staff Comments | 17 | |||

| 2. | Properties | 17 | |||

| 3. | Legal Proceedings | 18 | |||

| 4. | Submission of Matters to a Vote of Security Holders | 18 | |||

| Executive Officers of the Registrant | 19 | ||||

|

|

|

| |||

Part II. | 5. | Market for Registrant's Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities | 20 | |||

| 6. | Selected Financial Data | 22 | |||

| 7. | Management's Discussion and Analysis of Financial Condition and Results of Operations | 22 | |||

| 7A. | Quantitative and Qualitative Disclosures About Market Risk | 49 | |||

| 8. | Financial Statements and Supplementary Data | 50 | |||

| 9. | Changes in and Disagreements with Accountants on Accounting and Financial Disclosure | 104 | |||

| 9A. | Controls and Procedures | 104 | |||

| 9B. | Other Information | 105 | |||

|

|

|

| |||

Part III. | 10. | Directors and Executive Officers of the Registrant | 105 | |||

| 11. | Executive Compensation | 105 | |||

| 12. | Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters | 105 | |||

| 13. | Certain Relationships and Related Transactions | 108 | |||

| 14. | Principal Accounting Fees and Services | 108 | |||

|

|

|

| |||

Part IV. | 15. | Exhibits and Financial Statement Schedules | 109 | |||

Signatures | 110 | |||||

PART I.

Item 1. Business

Honeywell International Inc. (Honeywell) is a diversified technology and manufacturing company, serving customers worldwide with aerospace products and services, control, sensing and security technologies for buildings, homes and industry, turbochargers, automotive products, specialty chemicals, electronic and advanced materials, process technology for refining and petrochemicals, and energy efficient products and solutions for homes, business and transportation. Honeywell was incorporated in Delaware in 1985.

We maintain an internet website at http://www.honeywell.com. Our Annual Report on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K and any amendments to those reports, are available free of charge on our website under the heading "Investor Relations" (see "SEC Filings & Reports") immediately after they are filed with, or furnished to, the Securities and Exchange Commission (SEC). In addition, in this Form 10-K, the Company incorporates by reference certain information from parts of its proxy statement for the 2010 Annual Meeting of Stockholders, which we expect to file with the SEC on or about March 11, 2010, and which will also be available free of charge on our website.

Information relating to corporate governance at Honeywell, including Honeywell's Code of Business Conduct, Corporate Governance Guidelines and Charters of the Committees of the Board of Directors are also available, free of charge, on our website under the heading "Investor Relations" (see "Corporate Governance"), or by writing to Honeywell, 101 Columbia Road, Morris Township, New Jersey 07962, c/o Vice President and Corporate Secretary. Honeywell's Code of Business Conduct applies to all Honeywell directors, officers (including the Chief Executive Officer, Chief Financial Officer and Controller) and employees.

Major Businesses

We globally manage our business operations through four businesses that are reported as operating segments: Aerospace, Automation and Control Solutions, Specialty Materials and Transportation Systems. Financial information related to our operating segments is included in Note 23 of Notes to Financial Statements in "Item 8. Financial Statements and Supplementary Data."

The major products/services, customers/uses and key competitors of each of our operating segments follows:

Aerospace

Our Aerospace segment is a leading global provider of integrated avionics, engines, systems and service solutions for aircraft manufacturers, airlines, business and general aviation, military, space and airport operations.

|

|

|

|

|

|

|

Product/Service Classes | Major Products/Services | Major Customers/Uses | Key Competitors | |||

Turbine propulsion engines | TFE731 turbofan | Business, regional, general | United Technologies | |||

| ||||||

1

|

|

|

|

|

|

|

Product/Service Classes | Major Products/Services | Major Customers/Uses | Key Competitors | |||

Auxiliary power units | Airborne auxiliary power | Commercial, regional, | United Technologies | |||

| ||||||

Environmental control | Air management systems: | Commercial, regional and | Auxilec | |||

| ||||||

Electric power systems | Generators | Commercial, regional, | General Electric | |||

| ||||||

Engine systems and | Electronic and | Commercial, regional and | BAE Controls | |||

| ||||||

Avionics systems | Flight safety systems: | Commercial, business and | BAE | |||

| ||||||

2

|

|

|

|

|

|

|

Product/Service Classes | Major Products/Services | Major Customers/Uses | Key Competitors | |||

Aircraft and Obstruction | Inset lights | Commercial, regional, | Bruce | |||

| ||||||

Inertial sensor | Inertial sensor systems | Military and commercial | Astronautics-Kearfott | |||

| ||||||

Control products | Radar altimeters | Military aircraft | Ball Brothers | |||

| ||||||

Space products and | Guidance subsystems | Commercial and | BAE | |||

| ||||||

Management and | Maintenance/operation and | U.S. government space | Bechtel | |||

| ||||||

Landing systems | Wheels and brakes | Commercial airline, regional, | Dunlop Standard Aerospace | |||

| ||||||

Automation and Control Solutions

Our Automation and Control Solutions segment is a leading global provider of environmental and combustion controls, sensing controls, security and life safety products and services, scanning and mobility devices and process automation and building solutions and services for homes, buildings and industrial facilities.

|

|

|

|

|

|

|

Product/Service Classes | Major Products/Services | Major Customers/Uses | Key Competitors | |||

Environmental and | Heating, ventilating and | Original equipment | Bosch |

3

|

|

|

|

|

|

|

Product/Service Classes | Major Products/Services | Major Customers/Uses | Key Competitors | |||

| burners, boilers and |

| Schneider | |||

| ||||||

Environmental and | Consumer household | Package and materials | United Technologies | |||

| ||||||

Security and life safety | Security products and | OEMs | Bosch | |||

| ||||||

Scanning and mobility | Hand held and hands free | OEMs | Datalogic | |||

| ||||||

Process automation | Advanced control software | Refining and petrochemical | ABB | |||

| ||||||

Building solutions and | HVAC and building control | Building managers and | Ameresco | |||

| ||||||

4

Specialty Materials

Our Specialty Materials segment is a global leader in providing customers with high-performance specialty materials, including hydrocarbon processing technologies, catalysts, adsorbents, equipment and services, fluorine products, specialty films and additives, advanced fibers and composites, intermediates, specialty chemicals, electronic materials and chemicals.

|

|

|

|

|

|

|

Product/Service Classes | Major Products/Services | Major Customers/Uses | Key Competitors | |||

Resins & chemicals | Nylon polymer | Nylon for carpet fibers, | BASF | |||

| ||||||

Hydrofluoric acid (HF) | Anhydrous and aqueous | Fluorocarbons | Mexichem Flour | |||

| ||||||

Fluorocarbons | Refrigerants, aerosol and | Refrigeration | Arkema | |||

| ||||||

Fluorine specialties | Sulfur hexafluoride (SF 6 ) | Electric utilities | Air Products | |||

| ||||||

Nuclear services | UF 6 conversion services | Nuclear fuel | Cameco | |||

| ||||||

Research and fine chemicals | Oxime-based fine chemicals | Agrichemicals | Avecia | |||

| ||||||

Performance chemicals | HF derivatives | Diverse by product type | Atotech | |||

| ||||||

Advanced fibers & | High modulus polyethylene | Bullet resistant vests, | DuPont | |||

| ||||||

Specialty films | Cast nylon film | Food and pharmaceutical | American Biaxis | |||

| ||||||

Specialty additives | Polyethylene waxes | Coatings and inks | BASF | |||

| ||||||

Electronic chemicals | Ultra high-purity HF | Semiconductors | KMG | |||

| ||||||

Semiconductor materials and | Interconnect-dielectrics | Semiconductors | BASF | |||

| ||||||

5

|

|

|

|

|

|

|

Product/Service Classes | Major Products/Services | Major Customers/Uses | Key Competitors | |||

Catalysts, adsorbents and | Catalysts | Petroleum, refining, | Axens | |||

| ||||||

Process technology | Technology licensing and | Petroleum refining, | Axens | |||

| ||||||

Renewable fuels and | Technology licensing of | Agricultural products | Neste Oy | |||

| ||||||

Transportation Systems

Our Transportation Systems segment is one of the leading manufacturers of engine boosting systems for passenger cars and commercial vehicles, as well as a leading provider of automotive care and braking products.

|

|

|

|

|

|

|

Product/Service Classes | Major Products/Services | Major Customers/Uses | Key Competitors | |||

Charge-air systems | Turbochargers for gasoline | Passenger car, truck and | Borg-Warner | |||

| ||||||

Thermal systems | Exhaust gas coolers | Passenger car, truck and | Behr | |||

| ||||||

Aftermarket filters, spark | Oil, air, fuel, transmission | Automotive and heavy | AC Delco | |||

| ||||||

Brake hard parts and other | Disc brake pads and shoes | Automotive and heavy | Advics | |||

| ||||||

Aerospace Sales

Our sales to aerospace customers were 35 percent of our total sales in each of 2009, 2008 and 2007, respectively. Our sales to commercial aerospace original equipment manufacturers were 7, 9 and 10 percent of our total sales in 2009, 2008 and 2007, respectively. In addition, our sales to commercial aftermarket customers of aerospace products and services were 10, 11 and 11 percent of our total sales in 2009, 2008 and 2007, respectively. Our Aerospace results of operations can be impacted by various industry and economic conditions. See "Item 1A. Risk Factors."

6

U.S. Government Sales

Sales to the U.S. Government (principally by our Aerospace segment), acting through its various departments and agencies and through prime contractors, amounted to $4,288, $4,240 and $4,011 million in 2009, 2008 and 2007, respectively, which included sales to the U.S. Department of Defense, as a prime contractor and subcontractor, of $3,455, $3,412 and $3,192 million in 2009, 2008 and 2007, respectively. U.S. defense spending increased in 2009 and is also expected to increase in 2010. We do not expect to be significantly affected by any proposed changes in 2010 federal spending due principally to the varied mix of the government programs which impact us (OEM production, engineering development programs, aftermarket spares and repairs and overhaul programs). Our contracts with the U.S. Government are subject to audits, investigations, and termination by the government. See "Item 1A. Risk Factors."

Backlog

Our total backlog at December 31, 2009 and 2008 was $13,182 and $12,972 million, respectively. We anticipate that approximately $9,339 million of the 2009 backlog will be filled in 2010. We believe that backlog is not necessarily a reliable indicator of our future sales because a substantial portion of the orders constituting this backlog may be canceled at the customer's option.

Competition

We are subject to active competition in substantially all product and service areas. Competition is expected to continue in all geographic regions. Competitive conditions vary widely among the thousands of products and services provided by us, and vary by country. Depending on the particular customer or market involved, our businesses compete on a variety of factors, such as price, quality, reliability, delivery, customer service, performance, applied technology, product innovation and product recognition. Brand identity, service to customers and quality are generally important competitive factors for our products and services, and there is considerable price competition. Other competitive factors for certain products include breadth of product line, research and development efforts and technical and managerial capability. While our competitive position varies among our products and services, we believe we are a significant competitor in each of our major product and service classes. However, a number of our products and services are sold in competition with those of a large number of other companies, some of which have substantial financial resources and significant technological capabilities. In addition, some of our products compete with the captive component divisions of original equipment manufacturers. See Item 1A "Risk Factors" for further discussion.

International Operations

We are engaged in manufacturing, sales, service and research and development mainly in the United States, Europe, Canada, Asia and Latin America. U.S. exports and foreign manufactured products are significant to our operations. U.S. exports comprised 12, 10 and 10 percent of our total sales in 2009, 2008 and 2007, respectively. Foreign manufactured products and services, mainly in Europe, were 39 percent of our total sales in 2009, 2008 and 2007.

Approximately 18 percent of total 2009 sales of Aerospace-related products and services were exports of U.S. manufactured products and systems and performance of services such as aircraft repair and overhaul. Exports were principally made to Europe, Canada, Asia and Latin America. Foreign manufactured products and systems and performance of services comprised approximately 15 percent of total 2009 Aerospace sales. The principal manufacturing facilities outside the U.S. are in Europe, with less significant operations in Canada, Mexico and Asia.

Approximately 2 percent of total 2009 sales of Automation and Control Solutions products were exports of U.S. manufactured products. Foreign manufactured products and performance of services accounted for 57 percent of total 2009 Automation and Control Solutions sales. The principal manufacturing facilities outside the U.S. are in Europe with less significant operations in Asia and Canada.

7

Approximately 31 percent of total 2009 sales of Specialty Materials products and services were exports of U.S. manufactured products. Exports were principally made to Asia and Latin America. Foreign manufactured products and performance of services comprised 25 percent of total 2009 Specialty Materials sales. The principal manufacturing facilities outside the U.S. are in Europe, with less significant operations in Asia and Canada.

Exports of U.S. manufactured products comprised 1 percent of total 2009 sales of Transportation Systems products. Foreign manufactured products accounted for 68 percent of total 2009 sales of Transportation Systems. The principal manufacturing facilities outside the U.S. are in Europe, with less significant operations in Asia and Latin America.

Financial information including net sales and long-lived assets related to geographic areas is included in Note 24 of Notes to Financial Statements in "Item 8. Financial Statements and Supplementary Data". Information regarding the economic, political, regulatory and other risks associated with international operations is included in "Item 1A. Risk Factors."

Raw Materials

The principal raw materials used in our operations are generally readily available. We experienced no significant problems in the purchase of key raw materials and commodities in 2009. We are not dependent on any one supplier for a material amount of our raw materials, except related to phenol, a raw material used in our Specialty Materials segment. We purchase phenol under a supply agreement with one supplier.

The costs of certain key raw materials, including natural gas, benzene (the key component in phenol), ethylene, fluorspar and sulfur in our Specialty Materials business, steel, nickel, other metals and ethylene glycol in our Transportation Systems business, and nickel, titanium and other metals in our Aerospace business, are expected to remain volatile. In addition, in 2009 certain large long-term fixed supplier price agreements expired, primarily relating to components used by our Aerospace business, which in the aggregate, subjected us to higher volatility in certain component costs. We will continue to attempt to offset raw material cost increases with formula or long-term supply agreements, price increases and hedging activities where feasible. We do not anticipate that a shortage of raw materials will cause any material adverse impacts during 2010. See "Item 1A. Risk Factors" for further discussion.

We are highly dependent on our suppliers and subcontractors in order to meet commitments to our customers. In addition, many major components and product equipment items are procured or subcontracted on a single-source basis with a number of domestic and foreign companies. We maintain a qualification and performance surveillance process to control risk associated with such reliance on third parties. While we believe that sources of supply for raw materials and components are generally adequate, it is difficult to predict what effects shortages or price increases may have in the future. Furthermore, the inability of these suppliers to meet their quality and/or delivery commitments to us, due to bankruptcy, natural disasters or any other reason, may result in significant costs and delay, including those in connection with the required recertification of parts from new suppliers with our customers or regulatory agencies.

Patents, Trademarks, Licenses and Distribution Rights

Our segments are not dependent upon any single patent or related group of patents, or any licenses or distribution rights. We own, or are licensed under, a large number of patents, patent applications and trademarks acquired over a period of many years, which relate to many of our products or improvements to those products and which are of importance to our business. From time to time, new patents and trademarks are obtained, and patent and trademark licenses and rights are acquired from others. We also have distribution rights of varying terms for a number of products and services produced by other companies. In our judgment, those rights are adequate for the conduct of our business. We believe that, in the aggregate, the rights under our patents, trademarks and licenses are generally important to our operations, but we do not consider any patent, trademark or related

8

group of patents, or any licensing or distribution rights related to a specific process or product, to be of material importance in relation to our total business. See "Item 1A. Risk Factors" for further discussion.

We have registered trademarks for a number of our products and services, including Honeywell, Aclar, Ademco, Autolite, Bendix, Enovate, Fire-Lite, FRAM, Garrett, Hand Held, Holts, Jurid, Metrologic, MK, North, Notifier, Novar, Prestone, Redex, RMG, Simoniz, Spectra, System Sensor and UOP.

Research and Development

Our research activities are directed toward the discovery and development of new products, technologies and processes and the development of new uses for existing products. The Company has research and development activities in the U.S., Europe, India and China.

Research and development (R&D) expense totaled $1,330, $1,543 and $1,459 million in 2009, 2008 and 2007, respectively. The decrease in R&D expense in 2009 compared to 2008 of 14 percent was consistent with our 15 percent decrease in net sales. However, as a percentage of sales, R&D increased to 4.3 percent in 2009 compared to 4.2 percent in 2008. The increase as a percentage of sales was driven by lower sales, product, design and development costs in Automation and Control Solutions and Specialty Materials as well as expenditures on the development of turbocharging systems for new platforms, partially offset by lower R&D expense in Aerospace primarily due to major program completions. The increase in R&D expense in 2008 compared to 2007 of 6 percent was mainly due to additional product, design and development costs in Automation and Control Solutions, increased expenditures on the development of products for new aircraft platforms and increased expenditures on the development of turbocharging systems for new platforms. Customer-sponsored (principally the U.S. Government) R&D activities amounted to an additional $852, $903 and $881 million in 2009, 2008 and 2007, respectively.

Environment

We are subject to various federal, state, local and foreign government requirements regulating the discharge of materials into the environment or otherwise relating to the protection of the environment. It is our policy to comply with these requirements, and we believe that, as a general matter, our policies, practices and procedures are properly designed to prevent unreasonable risk of environmental damage, and of resulting financial liability, in connection with our business. Some risk of environmental damage is, however, inherent in some of our operations and products, as it is with other companies engaged in similar businesses.

We are and have been engaged in the handling, manufacture, use and disposal of many substances classified as hazardous by one or more regulatory agencies. We believe that, as a general matter, our policies, practices and procedures are properly designed to prevent unreasonable risk of environmental damage and personal injury, and that our handling, manufacture, use and disposal of these substances are in accord with environmental and safety laws and regulations. It is possible, however, that future knowledge or other developments, such as improved capability to detect substances in the environment or increasingly strict environmental laws and standards and enforcement policies, could bring into question our current or past handling, manufacture, use or disposal of these substances.

Among other environmental requirements, we are subject to the federal superfund and similar state and foreign laws and regulations, under which we have been designated as a potentially responsible party that may be liable for cleanup costs associated with current and former operating sites and various hazardous waste sites, some of which are on the U.S. Environmental Protection Agency's Superfund priority list. Although, under some court interpretations of these laws, there is a possibility that a responsible party might have to bear more than its proportional share of the cleanup costs if it is unable to obtain appropriate contribution from other responsible parties, we have not had to bear significantly more than our proportional share in multi-party situations taken as a whole.

9

We do not believe that existing or pending climate change legislation, regulation, or international treaties or accords are reasonably likely to have a material effect in the foreseeable future on the Company's business or markets that it serves, nor on its results of operations, capital expenditures or financial position. We will continue to monitor emerging developments in this area.

Further information, including the current status of significant environmental matters and the financial impact incurred for remediation of such environmental matters, if any, is included in "Item 7. Management's Discussion and Analysis of Financial Condition and Results of Operations," in Note 21 of Notes to Financial Statements in "Item 8. Financial Statements and Supplementary Data," and in "Item 1A. Risk Factors."

Employees

We have approximately 122,000 employees at December 31, 2009, of which approximately 54,000 were located in the United States.

10

Item 1A. Risk Factors

Cautionary Statement about Forward-Looking Statements

We have described many of the trends and other factors that drive our business and future results in "Item 7. Management's Discussion and Analysis of Financial Condition and Results of Operations", including the overview of the Company and each of our segments and the discussion of their respective economic and other factors and areas of focus for 2010. These sections and other parts of this report (including this Item 1A) contain "forward-looking statements" within the meaning of Section 21E of the Securities Exchange Act of 1934.

Forward-looking statements are those that address activities, events or developments that management intends, expects, projects, believes or anticipates will or may occur in the future. They are based on management's assumptions and assessments in light of past experience and trends, current economic and industry conditions, expected future developments and other relevant factors. They are not guarantees of future performance, and actual results, developments and business decisions may differ significantly from those envisaged by our forward-looking statements. We do not undertake to update or revise any of our forward-looking statements. Our forward-looking statements are also subject to risks and uncertainties that can affect our performance in both the near-and long-term. These forward-looking statements should be considered in light of the information included in this Form 10-K, including, in particular, the factors discussed below.

Risk Factors

Our business, operating results, cash flows and financial condition are subject to various risks and uncertainties, including, without limitation, those set forth below, any one of which could cause our actual results to vary materially from recent results or from our anticipated future results.

Industry and economic conditions may adversely affect the market and operating conditions of our customers, which in turn can affect demand for our products and services and our results of operations.

The operating results of our segments are impacted by general global industry and economic conditions that can cause changes in spending and capital investment patterns, demand for our products and services and the level of our manufacturing and shipping costs. The operating results of our Aerospace segment, which generated 35 percent of our consolidated revenues in 2009, are directly tied to cyclical industry and economic conditions, including global demand for air travel as reflected in new aircraft production, the deferral or cancellation of orders for new aircraft, delays in launch schedules for new aircraft platforms, the retirement of aircraft, global flying hours, and business and general aviation aircraft utilization rates, as well as changes in customer buying patterns with respect to aftermarket parts, supplier consolidation, factory transitions, capacity constraints, and the level and mix of U.S. Government appropriations for defense and space programs (as further discussed in other risk factors below). The challenging operating environment faced by the commercial airline industry is expected to continue and may be influenced by a wide variety of factors including global flying hours, aircraft fuel prices, labor issues, airline consolidation, airline insolvencies, terrorism and safety concerns as well as changes in regulations. Future terrorist actions or pandemic health issues could dramatically reduce both the demand for air travel and our Aerospace aftermarket sales and margins. The operating results of our Automation and Control Solutions (ACS) segment, which generated 41 percent of our consolidated revenues in 2009, are impacted by the level of global residential and commercial construction (including retrofits and upgrades), capital spending and operating expenditures on building and process automation, industrial plant capacity utilization and expansion, inventory levels in distribution channels, and global economic growth rates. Specialty Materials' operating results, which generated 13 percent of our consolidated revenues in 2009, are impacted by global economic growth rates, capacity utilization for chemical, industrial, refining, petrochemical and semiconductor plants, our customers' availability of capital for refinery construction and expansion, and commodity demand volatility. Transportation Systems' operating results, which generated 11 percent of our consolidated revenues in 2009, are impacted by global production and demand for automobiles and

11

trucks equipped with turbochargers, and regulatory changes regarding automobile and truck emissions and fuel economy, delays in launch schedules for new automotive platforms, and consumer demand and spending for automotive aftermarket and car care products. The challenging operating environment faced by global automotive and truck manufacturers is expected to continue and may be influenced by a wide variety of factors, including access to and terms of government assistance, ability to reduce high inventory levels, ability to reduce operating costs, and the ability of consumers to obtain financing for new vehicle purchases. Each of the segments is impacted by volatility in raw material prices (as further described below) and non-material inflation.

Raw material price fluctuations and the ability of key suppliers to meet quality and delivery requirements can increase the cost of our products and services and impact our ability to meet commitments to customers.

The cost of raw materials is a key element in the cost of our products, particularly in our Specialty Materials (benzene (the key component in phenol), natural gas, ethylene, fluorspar and sulfur), Transportation Systems (nickel, steel, other metals and ethylene glycol) and Aerospace (nickel, titanium and other metals) segments. Our inability to offset material price inflation through increased prices to customers, formula or long-term fixed price contracts with suppliers, productivity actions or through commodity hedges could adversely affect our results of operations.

Our manufacturing operations are also highly dependent upon the delivery of materials (including raw materials) by outside suppliers and their assembly of major components and subsystems used in our products in a timely manner and in full compliance with purchase order terms and conditions, quality standards, and applicable laws and regulations. In addition, many major components and product equipment items are procured or subcontracted on a single-source basis; in limited circumstances these suppliers are the sole source of the component or equipment. Our ability to manage inventory and meet delivery requirements may be constrained by our suppliers' ability to adjust delivery of long-lead time products during times of volatile demand. Our suppliers may fail to perform according to specifications as and when required and we may be unable to identify alternate suppliers or to otherwise mitigate the consequences of their non-performance. The supply chains for our businesses could also be disrupted by external events such as natural disasters, extreme weather events, pandemic health issues, terrorist actions, labor disputes, governmental actions and legislative or regulatory changes (e.g., product certification or stewardship requirements, sourcing restrictions, climate change or greenhouse gas emission standards, etc.). Our inability to fill our supply needs would jeopardize our ability to fulfill obligations under commercial and government contracts, which could, in turn, result in reduced sales and profits, contract penalties or terminations, and damage to customer relationships. Transitions to new suppliers may result in significant costs and delays, including those related to the required recertification of parts obtained from new suppliers with our customers and/or regulatory agencies. In addition, because our businesses cannot always immediately adapt their cost structure to changing market conditions, our manufacturing capacity for certain products may at times exceed or fall short of our production requirements, which could adversely impact our operating costs, profitability and customer and supplier relationships.

Our future growth is largely dependent upon our ability to develop new technologies that achieve market acceptance with acceptable margins.

Our businesses operate in global markets that are characterized by rapidly changing technologies and evolving industry standards. Accordingly, our future growth rate depends upon a number of factors, including our ability to (i) identify emerging technological trends in our target end-markets, (ii) develop and maintain competitive products, (iii) enhance our products by adding innovative features that differentiate our products from those of our competitors and prevent commoditization of our products, (iv) develop, manufacture and bring products to market quickly and cost-effectively, and (v) develop and retain individuals with the requisite expertise.

Our ability to develop new products based on technological innovation can affect our competitive position and requires the investment of significant resources. These development efforts divert resources from other potential investments in our businesses, and they may not lead to the

12

development of new technologies or products on a timely basis or that meet the needs of our customers as fully as competitive offerings. In addition, the markets for our products may not develop or grow as we currently anticipate. The failure of our technologies or products to gain market acceptance due to more attractive offerings by our competitors could significantly reduce our revenues and adversely affect our competitive standing and prospects.

Protecting our intellectual property is critical to our innovation efforts.

We own or are licensed under a large number of U.S. and non-U.S. patents and patent applications, trademarks and copyrights. Our intellectual property rights may expire or be challenged, invalidated or infringed upon by third parties or we may be unable to maintain, renew or enter into new licenses of third party proprietary intellectual property on commercially reasonable terms. In some non-U.S. countries, laws affecting intellectual property are uncertain in their application, which can affect the scope or enforceability of our patents and other intellectual property rights. Any of these events or factors could diminish or cause us to lose the competitive advantages associated with our intellectual property, subject us to judgments, penalties and significant litigation costs, and/or temporarily or permanently disrupt our sales and marketing of the affected products or services.

An increasing percentage of our sales and operations is in non-U.S. jurisdictions and is subject to the economic, political, regulatory and other risks of international operations.

Our international operations, including U.S. exports, comprise a growing proportion of our operating results. Our strategy calls for increasing sales to and operations in overseas markets, including developing markets such as Mexico, China, India, the Middle East and Eastern Europe. In 2009, 51 percent of our total sales (including products manufactured in the U.S. and in international locations) were outside of the U.S. including 28 percent in Europe and 11 percent in Asia. Risks related to international operations include exchange control regulations, wage and price controls, employment regulations, foreign investment laws, import, export and other trade restrictions (such as embargoes and trade restrictions), changes in regulations regarding transactions with state-owned enterprises, nationalization of private enterprises, government instability, and our ability to hire and maintain qualified staff and maintain the safety of our employees in these regions. The cost of compliance with increasingly complex and often conflicting regulations worldwide can also impair our flexibility in modifying product, marketing, pricing or other strategies for growing our businesses, as well as our ability to improve productivity and maintain acceptable operating margins.

As we continue to grow our businesses internationally, our operating results could be increasingly affected by the relative strength of the European and Asian economies and the impact of exchange rate fluctuations. We do have a policy to reduce the risk of volatility through hedging activities, but such activities bear a financial cost and may not always be available to us and may not be successful in eliminating such volatility.

We may be required to recognize impairment charges for our long-lived assets or available for sale investments.

At December 31, 2009, the net carrying value of long-lived assets (property, plant and equipment, goodwill and other intangible assets) and available for sale securities totaled approximately $17.5 billion and $0.1 billion, respectively. In accordance with generally accepted accounting principles, we periodically assess these assets to determine if they are impaired. Significant negative industry or economic trends, disruptions to our business, unexpected significant changes or planned changes in use of the assets, divestitures and market capitalization declines may result in impairments to goodwill and other long-lived assets. An other than temporary decline in the market value of our available for sale securities may also result in an impairment charge. Future impairment charges could significantly affect our results of operations in the periods recognized. Impairment charges would also reduce our consolidated shareowners' equity and increase our debt-to-total-capitalization ratio, which could negatively impact our credit rating and access to the public debt and equity markets.

13

A change in the level of U.S. Government defense and space funding or the mix of programs to which such funding is allocated could adversely impact sales of Aerospace's defense and space-related product and services.

Sales of our defense and space-related products and services are largely dependent upon government budgets, particularly the U.S. defense budget. Sales as a prime contractor and subcontractor to the U.S. Department of Defense comprised approximately 32 and 11 percent of Aerospace and total sales, respectively, for the year ended December 31, 2009. Although U.S. defense spending increased in 2009 and is expected to increase again in 2010, we cannot predict the extent to which total funding and/or funding for individual programs will be included, increased or reduced as part of the 2011 and subsequent budgets ultimately approved by Congress, or be included in the scope of separate supplemental appropriations. We also cannot predict the impact of potential changes in priorities due to military transformation and planning and/or the nature of war-related activity on existing, follow-on or replacement programs. A shift in defense or space spending to programs in which we do not participate and/or reductions in funding for or termination of existing programs could adversely impact our results of operations.

As a supplier of military and other equipment to the U.S. Government, we are subject to unusual risks, such as the right of the U.S. Government to terminate contracts for convenience and to conduct audits and investigations of our operations and performance.

In addition to normal business risks, companies like Honeywell that supply military and other equipment to the U.S. Government are subject to unusual risks, including dependence on Congressional appropriations and administrative allotment of funds, changes in governmental procurement legislation and regulations and other policies that reflect military and political developments, significant changes in contract scheduling, complexity of designs and the rapidity with which they become obsolete, necessity for constant design improvements, intense competition for U.S. Government business necessitating increases in time and investment for design and development, difficulty of forecasting costs and schedules when bidding on developmental and highly sophisticated technical work, and other factors characteristic of the industry, such as contract award protests and delays in the timing of contract approvals. Changes are customary over the life of U.S. Government contracts, particularly development contracts, and generally result in adjustments of contract prices.

Our contracts with the U.S. Government are subject to audits. Like many other government contractors, we have received audit reports that recommend downward price adjustments to certain contracts or changes to certain accounting systems or controls to comply with various government regulations. We have made adjustments and paid voluntary refunds in appropriate cases and may do so in the future.

U.S. Government contracts are subject to termination by the government, either for the convenience of the government or for our failure to perform under the applicable contract. In the case of a termination for convenience, we are typically entitled to reimbursement for our allowable costs incurred, plus termination costs and a reasonable profit. If a contract is terminated by the government for our failure to perform we could be liable for additional costs incurred by the government in acquiring undelivered goods or services from any other source and any other damages suffered by the government.

We are also subject to government investigations of business practices and compliance with government procurement regulations. If Honeywell or one of its businesses were charged with wrongdoing as a result of any such investigation or other government investigations (including violations of certain environmental or export laws), it could be suspended from bidding on or receiving awards of new government contracts, suspended from contract performance pending the completion of legal proceedings and/or have its export privileges suspended. The U.S. Government also reserves the right to debar a contractor from receiving new government contracts for fraudulent, criminal or other egregious misconduct. Debarment generally does not exceed three years.

14

Our reputation and ability to do business may be impacted by the improper conduct of employees, agents or business partners.

We cannot ensure that our extensive compliance controls, policies and procedures will in all instances protect us from reckless or criminal acts committed by our employees, agents or business partners that would violate the laws of the jurisdictions in which the Company operates, including laws governing payments to government officials, competition and data privacy. Any improper actions could subject us to civil or criminal investigations, monetary and non-monetary penalties and could adversely impact our ability to conduct business, results of operations and reputation.

Changes in legislation or government regulations or policies can have a significant impact on our results of operations.

The sales and margins of each of our segments are directly impacted by government regulations. Safety and performance regulations (including mandates of the Federal Aviation Administration and other similar international regulatory bodies requiring the installation of equipment on aircraft), product certification requirements and government procurement practices can impact Aerospace sales, research and development expenditures, operating costs and profitability. The demand for and cost of providing Automation and Control Solutions products, services and solutions can be impacted by fire, security, safety, health care, environmental and energy efficiency standards and regulations. Specialty Materials' results of operations can be affected by environmental (e.g. government regulation of fluorocarbons), safety and energy efficiency standards and regulations, while emissions and energy efficiency standards and regulations can impact the demand for turbochargers in our Transportation Systems segment. Legislation or regulations regarding areas such as labor and employment, employee benefit plans, tax, health and safety matters, import, export and trade, intellectual property, product certification, product liability and environmental remediation may impact the results of each of our operating segments and our consolidated results.

Completed acquisitions may not perform as anticipated or be integrated as planned, and divestitures may not occur as planned.

We regularly review our portfolio of businesses and pursue growth through acquisitions and seek to divest non-core businesses. We may not be able to complete transactions on favorable terms, on a timely basis or at all. In addition, our results of operations and cash flows may be adversely impacted by (i) the failure of acquired businesses to meet or exceed expected returns, (ii) the discovery of unanticipated issues or liabilities, (iii) the failure to integrate acquired businesses into Honeywell on schedule and/or to achieve synergies in the planned amount or within the expected timeframe, (iv) the inability to dispose of non-core assets and businesses on satisfactory terms and conditions and within the expected timeframe, and (v) the degree of protection provided by indemnities from sellers of acquired companies and the obligations under indemnities provided to purchasers of our divested businesses.

We cannot predict with certainty the outcome of litigation matters, government proceedings and other contingencies and uncertainties.

We are subject to a number of lawsuits, investigations and disputes (some of which involve substantial amounts claimed) arising out of the conduct of our business, including matters relating to commercial transactions, government contracts, product liability (including asbestos), prior acquisitions and divestitures, employment, employee benefits plans, intellectual property, import and export matters and environmental, health and safety matters. Resolution of these matters can be prolonged and costly, and the ultimate results or judgments are uncertain due to the inherent uncertainty in litigation and other proceedings. Moreover, our potential liabilities are subject to change over time due to new developments, changes in settlement strategy or the impact of evidentiary requirements, and we may be required to pay damage awards or settlements, or become subject to damage awards or settlements, that could have a material adverse effect on our results of operations, cash flows and financial condition. While we maintain insurance for certain risks, the amount of our insurance coverage may not be adequate to cover the total amount of all insured claims and liabilities. It also is

15

not possible to obtain insurance to protect against all our operational risks and liabilities. The incurrence of significant liabilities for which there is no or insufficient insurance coverage could adversely affect our results of operations, cash flows, liquidity and financial condition.

Our operations and the prior operations of predecessor companies expose us to the risk of material environmental liabilities.

Mainly because of past operations and operations of predecessor companies, we are subject to potentially material liabilities related to the remediation of environmental hazards and to claims of personal injuries or property damages that may be caused by hazardous substance releases and exposures. We have incurred remedial response and voluntary clean-up costs for site contamination and are a party to lawsuits and claims associated with environmental and safety matters, including past production of products containing hazardous substances. Additional lawsuits, claims and costs involving environmental matters are likely to continue to arise in the future. We are subject to various federal, state, local and foreign government requirements regulating the discharge of materials into the environment or otherwise relating to the protection of the environment. These laws and regulations can impose substantial fines and criminal sanctions for violations, and require installation of costly equipment or operational changes to limit emissions and/or decrease the likelihood of accidental hazardous substance releases. We incur, and expect to continue to incur capital and operating costs to comply with these laws and regulations. In addition, changes in laws, regulations and enforcement of policies, the discovery of previously unknown contamination or new technology or information related to individual sites, or the imposition of new clean-up requirements or remedial techniques could require us to incur costs in the future that would have a negative effect on our financial condition or results of operations.

Our expenses include significant costs related to employee and retiree health benefits.

With approximately 122,000 employees, including approximately 54,000 in the U.S., our expenses relating to employee health and retiree health benefits are significant. In recent years, we have experienced significant increases in certain of these costs, largely as a result of economic factors beyond our control, in particular, ongoing increases in health care costs well in excess of the rate of inflation. Continued increasing health-care costs, legislative or regulatory changes, and volatility in discount rates, as well as changes in other assumptions used to calculate retiree health benefit expenses, may adversely affect our financial position and results of operations.

Risks related to our defined benefit pension plans may adversely impact our results of operations and cash flow.

Significant changes in actual investment return on pension assets, discount rates, and other factors could adversely affect our results of operations and pension contributions in future periods. U.S. generally accepted accounting principles require that we calculate income or expense for the plans using actuarial valuations. These valuations reflect assumptions about financial markets and interest rates, which may change based on economic conditions. Funding requirements for our U.S. pension plans may become more significant. However, the ultimate amounts to be contributed are dependent upon, among other things, interest rates, underlying asset returns and the impact of legislative or regulatory changes related to pension funding obligations. For a discussion regarding the significant assumptions used to estimate pension expense, including discount rate and the expected long-term rate of return on plan assets, and how our financial statements can be affected by pension plan accounting policies, see "Critical Accounting Policies" included in "Item 7. Management's Discussion and Analysis of Financial Condition and Results of Operations."

Additional tax expense or additional tax exposures could affect our future profitability.

We are subject to income taxes in both the United States and various non-U.S. jurisdictions, and our domestic and international tax liabilities are dependent upon the distribution of income among these different jurisdictions. In 2009, our tax expense represented 26.5 percent of our income before

16

tax, and includes estimates of additional tax which may be incurred for tax exposures and reflects various estimates and assumptions, including assessments of future earnings of the Company that could effect the valuation of our deferred tax assets. Our future results could be adversely affected by changes in the effective tax rate as a result of a change in the mix of earnings in countries with differing statutory tax rates, changes in the overall profitability of the Company, changes in tax legislation, changes in the valuation of deferred tax assets and liabilities, the results of audits and examinations of previously filed tax returns and continuing assessments of our tax exposures.

Volatility of credit markets or macro-economic factors could adversely affect our business.

Changes in U.S. and global financial and equity markets, including market disruptions, limited liquidity, and interest rate volatility, may increase the cost of financing as well as the risks of refinancing maturing debt. In addition, our borrowing costs can be affected by short and long-term ratings assigned by independent rating agencies. A decrease in these ratings could increase our cost of borrowing.

Delays in our customers' ability to obtain financing, or the unavailability of financing to our customers, could adversely affect our results of operations and cash flow. The inability of our suppliers to obtain financing could result in the need to transition to alternate suppliers, which could result in significant incremental cost and delay, as discussed above. Lastly, disruptions in the U.S. and global financial markets could impact the financial institutions with which we do business.

Item 1B. Unresolved Staff Comments

Not Applicable

Item 2. Properties

We have approximately 1,300 locations consisting of plants, research laboratories, sales offices and other facilities. Our headquarters and administrative complex is located at Morris Township, New Jersey. Our plants are generally located to serve large marketing areas and to provide accessibility to raw materials and labor pools. Our properties are generally maintained in good operating condition. Utilization of these plants may vary with sales to customers and other business conditions; however, no major operating facility is significantly idle. We own or lease warehouses, railroad cars, barges, automobiles, trucks, airplanes and materials handling and data processing equipment. We also lease space for administrative and sales staffs. Our properties and equipment are in good operating condition and are adequate for our present needs. We do not anticipate difficulty in renewing existing leases as they expire or in finding alternative facilities.

Our principal plants, which are owned in fee unless otherwise indicated, are as follows:

|

|

|

|

|

| Aerospace |

| ||

Anniston, AL (leased) | South Bend, IN | Greer, SC | ||

| Automation and Control Solutions |

| ||

Phoenix, AZ (leased) | Skaneateles Falls, NY | Juarez, Mexico (partially leased) |

17

|

|

|

|

|

| Specialty Materials |

| ||

Mobile, AL | Geismar, LA | Colonial Heights, VA | ||

| Transportation Systems |

| ||

Shanghai, China | Atessa, Italy | Mexicali, Mexico (partially leased) |

Item 3. Legal Proceedings

We are subject to a number of lawsuits, investigations and claims (some of which involve substantial amounts) arising out of the conduct of our business. See a discussion of environmental, asbestos and other litigation matters in Note 21 of Notes to Financial Statements in "Item 8. Financial Statements and Supplementary Data."

Environmental Matters Involving Potential Monetary Sanctions in Excess of $100,000

The United States Environmental Protection Agency and the United States Department of Justice ("federal authorities") are investigating whether the storage of certain sludges generated during uranium hexafluoride production at our Metropolis, Illinois facility has been in compliance with the requirements of the Resource Conservation and Recovery Act. The federal authorities have convened a grand jury in this matter. This storage issue was previously voluntarily disclosed to the Illinois Environmental Protection Agency, with whom Honeywell has been working to resolve the matter. The Company has met with the federal authorities and is cooperating fully with the investigation. Although the outcome of this matter cannot be predicted with certainty, we do not believe that it will have a material adverse effect on our consolidated financial position, consolidated results of operations or operating cash flows.

Item 4. Submission of Matters to a Vote of Security Holders

Not Applicable.

18

Executive Officers of the Registrant

The executive officers of Honeywell, listed as follows, are elected annually by the Board of Directors. There are no family relationships among them.

|

|

|

Name, Age, | Business Experience | |

David M. Cote (a), 57 | Chairman of the Board and Chief Executive Officer since July 2002. | |

Alexandre Ismail, 44 | President and Chief Executive Officer Transportation Systems since April 2009. President Turbo Technologies from November 2008 to April 2009. President Global Passengers Vehicles from August 2006 to November 2008. Vice President and General Manager Turbo Technologies EMEA & India from September 2003 to August 2006. | |

Roger Fradin, 56 | President and Chief Executive Officer Automation and Control Solutions since January 2004. | |

Timothy O. Mahoney, 53 | President and Chief Executive Officer Aerospace since September 2009. Vice President Aerospace Engineering and Technology and Chief Technology Officer from March 2007 to August 2009. President of Air Transport and Regional from July 2005 to March 2007. Vice President and General Manager Aviation Aftermarket Services from July 2004 to July 2005. | |

Andreas C. Kramvis, 57 | President and Chief Executive Officer Specialty Materials since March 2008. President of Environmental and Combustion Controls from September 2002 to February 2008. | |

David J. Anderson, 60 | Senior Vice President and Chief Financial Officer since June 2003. | |

Larry E. Kittelberger, 61 | Senior Vice President Technology and Operations since October 2006. Senior Vice President Administration and Chief Information Officer from August 2001 to October 2006. | |

Katherine L. Adams, 45 | Senior Vice President and General Counsel since April 2009. Vice President and General Counsel from September 2008 to April 2009. Vice President and General Counsel for Specialty Materials from February 2005 to September 2008. | |

Mark R. James, 48 | Senior Vice President Human Resources and Communications since November 2007. Vice President of Human Resources and Communications for Aerospace from October 2004 to November 2007. Vice President of Human Resources for Aerospace Electronic Systems from March 2001 to October 2004.

|

| ||||||||||||||||||||

(a) |

| Also a Director.

| ||||||||||||||||||

19

Part II.

Item 5. Market for Registrant's Common Equity, Related Stockholder

Matters and Issuer Purchases of Equity Securities

Market and dividend information for Honeywell's common stock is included in Note 26 of Notes to Financial Statements in "Item 8. Financial Statements and Supplementary Data."

The number of record holders of our common stock at December 31, 2009 was 64,617.

Honeywell did not purchase any of its common stock, par value $1 per share, for the year ending December 31, 2009. Under the Company's previously reported $3.0 billion share repurchase program, $1.3 billion remained available as of December 31, 2009 for additional share repurchases. The amount and timing of future repurchases may vary depending on market conditions and the level of operating and other investing activities.

20

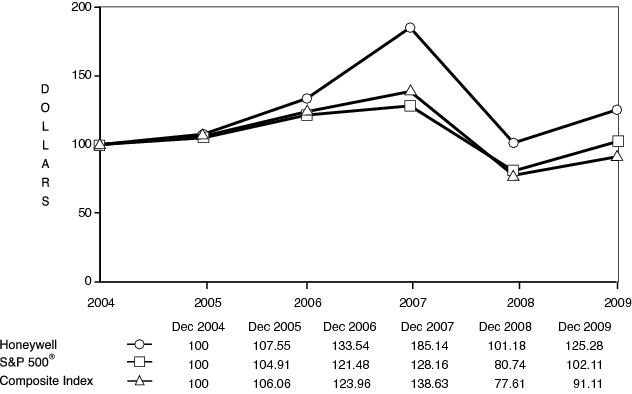

Performance Graph

The following graph compares the five-year cumulative total return on our Common Stock to the total returns on the Standard & Poor's 500 Stock Index and a composite of Standard & Poor's Aerospace and Defense and Industrial Conglomerates indices, on an equally weighted basis (the "Composite Index"). The selection and weighting of the Aerospace and Defense component of the Composite Index was deemed appropriate in light of the fact that Honeywell's Aerospace segment has accounted for, on average, approximately 50% of our aggregate segment profit over the past three completed fiscal years. The selection and weighting of the Industrial Conglomerates component of the Composite Index reflects the diverse and distinct range of non-aerospace businesses conducted by Honeywell and their contribution to our overall segment profits. The annual changes for the five-year period shown in the graph are based on the assumption that $100 had been invested in Honeywell stock and each index on December 31, 2004 and that all dividends were reinvested.

21

HONEYWELL INTERNATIONAL INC.

Item 6. Selected Financial Data

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

| Years Ended December 31, | ||||||||||||||||||||||||||||||||||

2009 | 2008 | 2007 | 2006 | 2005 | |||||||||||||||||||||||||||||||

| (Dollars in millions, except per share amounts) | ||||||||||||||||||||||||||||||||||

Results of Operations |

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

Net sales |

| $ |

| 30,908 |

| $ |

| 36,556 |

| $ |

| 34,589 |

| $ |

| 31,367 |

| $ |

| 27,652 | |||||||||||||||

Net income attributable to Honeywell |

| 2,153 |

| 2,792 |

| 2,444 |

| 2,078 |

| 1,564 | |||||||||||||||||||||||||

Per Common Share |

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

Earnings from continuing operations: |

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

Basic |

| 2.86 |

| 3.79 |

| 3.20 |

| 2.53 |

| 1.85 | |||||||||||||||||||||||||

Assuming dilution |

| 2.85 |

| 3.76 |

| 3.16 |

| 2.51 |

| 1.84 | |||||||||||||||||||||||||

Dividends |

| 1.21 |

| 1.10 |

| 1.00 |

| 0.9075 |

| 0.825 | |||||||||||||||||||||||||

Financial Position at Year-End |

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

Property, plant and equipment-net |

| 4,847 |

| 4,934 |

| 4,985 |

| 4,797 |

| 4,658 | |||||||||||||||||||||||||

Total assets |

| 36,004 |

| 35,490 |

| 33,805 |

| 30,941 |

| 31,633 | |||||||||||||||||||||||||

Short-term debt |

| 1,361 |

| 2,510 |

| 2,238 |

| 1,154 |

| 2,024 | |||||||||||||||||||||||||

Long-term debt |

| 6,246 |

| 5,865 |

| 5,419 |

| 3,909 |

| 3,082 | |||||||||||||||||||||||||

Total debt |

| 7,607 |

| 8,375 |

| 7,657 |

| 5,063 |

| 5,106 | |||||||||||||||||||||||||

Shareowners' equity(1) |

| 8,954 |

| 7,269 |

| 9,293 |

| 9,777 |

| 10,806 | |||||||||||||||||||||||||

| ||||||||||||||||||||

(1) |

| For the year ended December 31, 2006 shareowners' equity includes a reduction of $1,512 related to the adoption of revised accounting guidance for "Employers' Accounting for Defined Benefit Pension and Other Postretirement Plans".

| ||||||||||||||||||

Item 7. Management's Discussion and Analysis of Financial Condition and

Results of Operations

The following Management's Discussion and Analysis of Financial Condition and Results of Operations ("MD&A") is intended to help the reader understand the results of operations and financial condition of Honeywell International Inc. ("Honeywell") for the three years ended December 31, 2009. All references to Notes relate to Notes to the Financial Statements in "Item 8-Financial Statements and Supplementary Data".

CONSOLIDATED RESULTS OF OPERATIONS

Net Sales